Preventive Maintenance Prevents Avoidable Repairs

Did you know our preventive maintenance inspection often catches minor issues before they become major problems? These three common issues are accidents just waiting to happen. In addition, their repair costs are 100% avoidable through regular PMP visits.

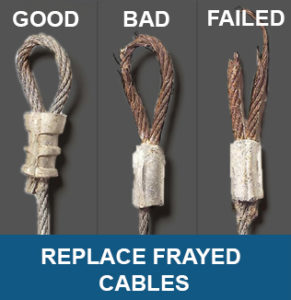

1. Frayed Door Cables

Frayed cables are an accident waiting to happen. A frayed cable could fail at any point. As a result, the door could fall on any vehicles, products or people who are in the doorway.

Often frayed cables are overlooked by your staff. However, it is one of the first things our technicians look for when using our multi-point inspection checklist during their PMP visit.

2. Broken Dock Welds

Broken welds are the main cause for major repair costs on docks. In addition, it can lead to serious injury if the weld on the dock lip fails when a forklift is passing over.

Our technicians will search for any broken welds that could lead to equipment failure. Then they will mark it with paint for a future fix.

3. Door Creep

When overhead door springs are not balanced and/or tighten on a regular basis, the door will creep back down into the opening. As a result, it creates an impact hazard for forklifts during loading and unloading.

Complimentary spring lubrication and adjustment are included with the PMP to prolong the spring’s lifespan and prevent door creep