Enershield Air Barriers create the tightest seal to separate areas of different temperatures, preventing extreme outside weather and contamination from entering the building.

Company: Maple Leaf Foods

City: Brampton, Ontario

THE OPPORTUNITY

The chiller room for the customer’s product had a door which was open through out the day. Being compliant to food safety regulations, the set point of their cooling system was reduced in order to maintain required temperatures. The resultant energy costs were expensive and the customer is always looking for methods to improve on food safety imperatives. The request to install a high speed fabric door was made to allow for the doorway to be closed more frequently to achieve their goal.

THE SOLUTION

Upon investigation, it was found that, based on the frequency of staff entering and leaving the chiller room, a high speed fabric door would be open more than 95% of the operating time of the facility and wouldn’t achieve the proposed goal.

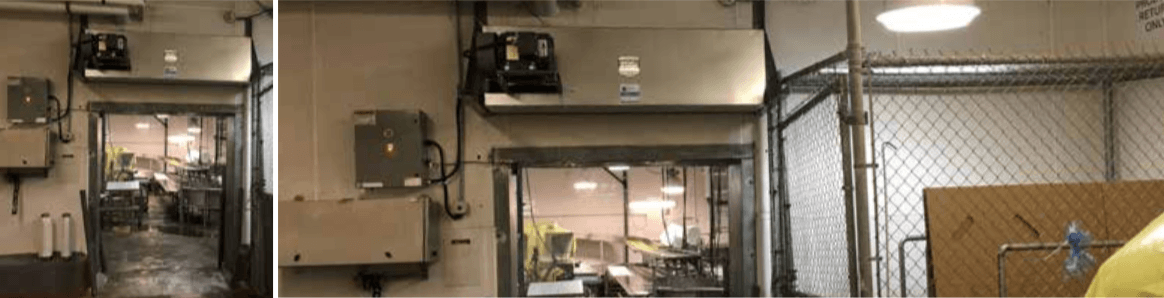

Rather, Northern Dock Systems provided a recommendation for an overhead air barrier to be installed. With this product the doorway would be open and closed at the same time, reduc- ing the infiltration of warm, humid air from the production area, while keeping the conditioned air in the chiller room. This would be accomplished even while staff were entering and exiting the room. During non-operating hours, the existing sliding insulated cooler door would be closed and the air barrier would turn off automatically.

Temperature and Humidity Improvements

A site assessment and measurements were completed to specify the correct product and application. Working with the Quality Control staff we ensured that operating processes within their HACCP system were complete to maintain all food safety requirements.