Clean up debris in the pit, lubricate components and repaired air-powered dock leveler

Project Overview

We were called into an emergency service repair for an air-powered dock leveler that was not lifting for one of our retail customers in Edmonton.

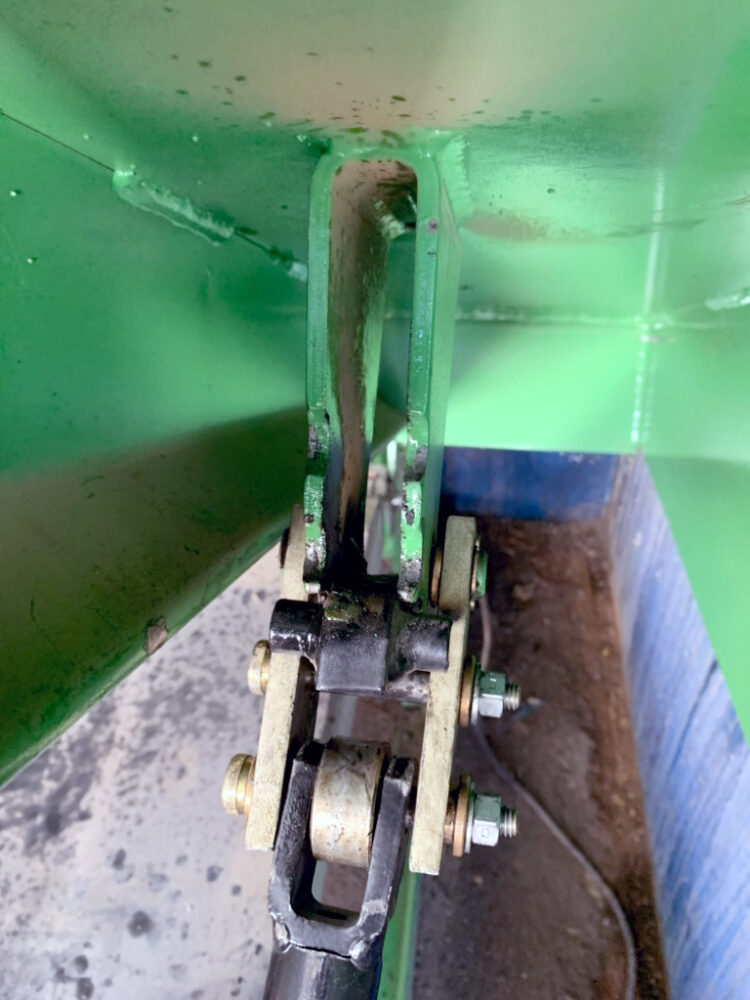

When the technicians arrived, he first put up the safety bars, cleaned out the pit of debris and lubricated all components while he troubleshot the problem. Through root cause discovery he was able to discover that there was a bent assisting lift arm and a broken bracket that was preventing the dock from lifting.

During emergency service repair of the dock leveler, our technician:

- Cleaned up the pit of debris.

- Lubricated all components.

- Removed bent assisting lift arm and installed new connecting rod.

- Cleaned pit lubricate all components.

- Welded broken bracket back into the frame and grinned off to make flash.

Welded broken bracket back into the frame and grinned off to make flash

Removed bent assisting lift arm and installed new connecting rod

However, after testing the operation of the dock leveler twice, our emergency service technician discovered even though the was repaired and operational, the whole system was compromised and could result in another failure in the future.

In order to prevent future failures, a hydraulic conversion would be a cost-efficient and long-term solution. Our technicians and service team are always looking for ways to not only decrease downtime at the moment but in long the run.