Door Creep is the #1 Reason for Emergency Service on Overhead Doors

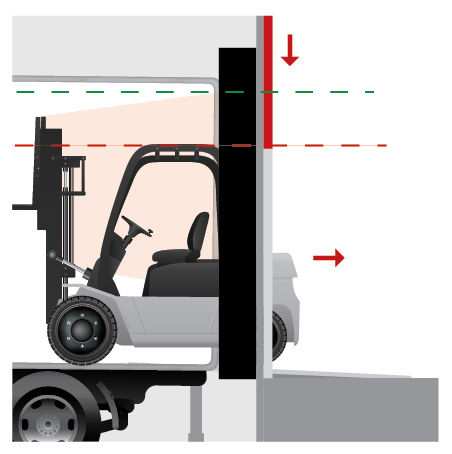

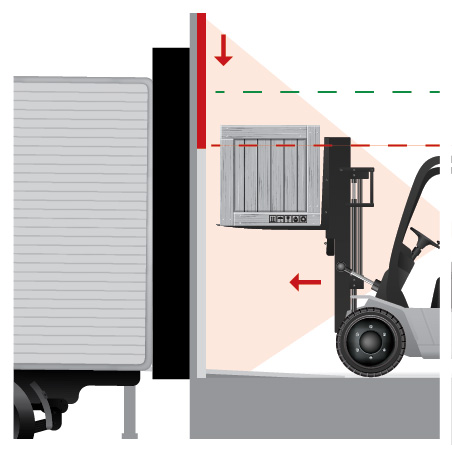

Door Creep

When overhead door springs are not balanced and/or tighten on a regular basis, the door will creep back down into the opening. As a result, it creates an impact hazard for forklifts during loading and unloading.

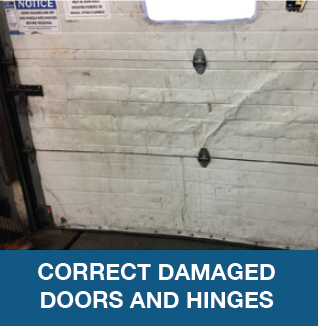

Consequently, when a door panel is impacted, it causes immediate downtime and leads to unnecessary emergency repair costs. However, these repair costs are 100% avoidable through regular preventive maintenance visits.

Preventive Maintenance Stops Door Creep and Overhead Door Impacts

Prevent workplace accidents and be prepared for any safety inspections and/or food audits by scheduling regular preventive maintenance visits. During a preventive maintenance visit, our technicians use a multi-point inspection sheet to keep you in compliance with strict Ministry of Labour and food agency regulations.

This multi-point inspection checklist makes sure that your overhead door has been properly inspected for any safety issues such as:

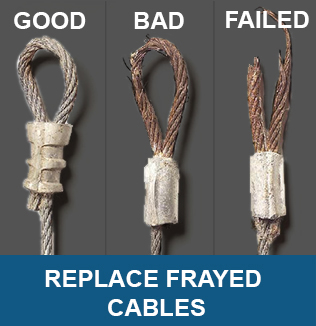

- Inspect wearable parts such as cables, hinges and rollers.

- Identify any frayed cables or other safety issues.

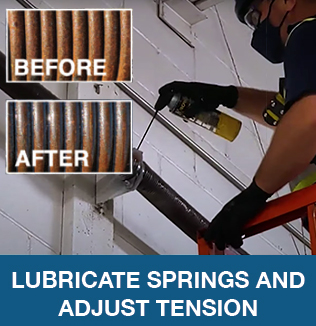

- Test each door for proper spring tension.

- Adjust spring tension and balance door, if needed.

- Complimentary spring lubrication to prolong the spring’s lifespan.

The Most Common Adjustments for Overhead Doors

Six Reasons to Use an Overhead Door Preventive Maintenance Program

- Increase operational efficiency by preventing emergency service repairs or costly downtime.

- Keep workers safe and prevent workplace injuries.

- Prolong lifespan by staying current to the manufacturer’s warranty with proper maintenance.

- Get first-time fixes from a team that specializes in first-time fixes and root cause discovery.

- Provide peace of mind by being prepared for safety inspections, food audits and strict Ministry of Labour regulations.

- Stay informed on the equipment you do not have time or training to inspect yourself.

Pass Inspections with Flying Colours

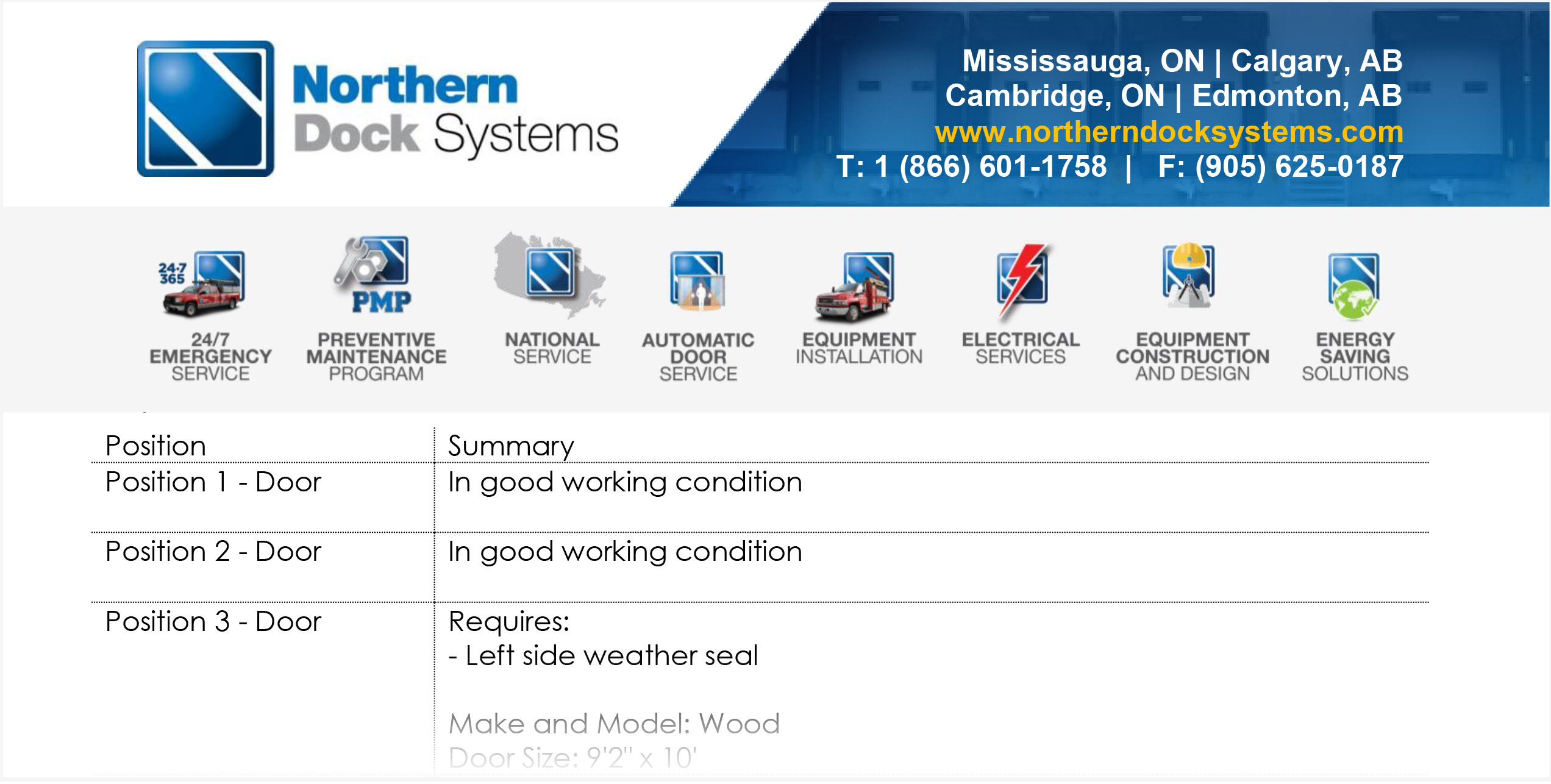

After we complete a preventive maintenance visit at your location, we will provide you with a PMP report.

This report has a full breakdown for each piece of equipment we inspected along with an itemized list of what we did to get you up to code. In addition to this breakdown, we will provide you with before and after pictures of any repairs we did to fix any health and safety concerns.

As a result, the next time the Ministry of Labour and/or food agencies comes knocking on your door; you can feel confident that you have done your due diligence.

Preventive Maintenance for All Equipment Types

Contact us to learn more about our detailed Preventive Maintenance Program. We have product-specific checklists for all equipment types including overhead doors, dock levelers, fire door drop tests, HVLS fans and more.