Project Overview

Old Loading Dock and Drive-In Door

Lake City Foods in Mississauga needed an upgrade to their existing loading dock position since the dock was old, worn and too short for today’s standards. Additionally, they were looking to convert this drive-in door to a dock door to keep up with deliveries from trailers.

Converting Drive-In Door to Dock Door

We got to work on filling the existing 12’x50’x48″ deep pit that had a stairwell with concrete and sealant to get it level with the floor of the food manufacturing plant. Next, we add a 6’x6′ dock pit at the end of the floor infill along with another 6’x6′ dock pit to replace the older and shorter dock pit at the other door. After that, we close up the drive-in doors opening from 12’x16′ to 8’x10′ to create a tight seal around trailers.

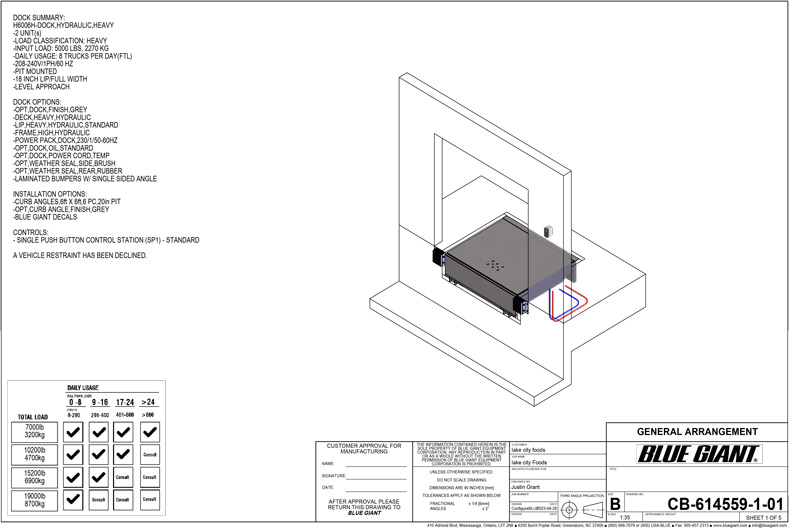

Hydraulic Dock Levelers

After construction, our technicians installed two new Blue Giant Hydraulic Dock Levelers with Steel Face Dock Bumpers to protect the new docks. These hydraulic dock levellers are easy to operate with push-button controls and have a rust-resistant powder coat.

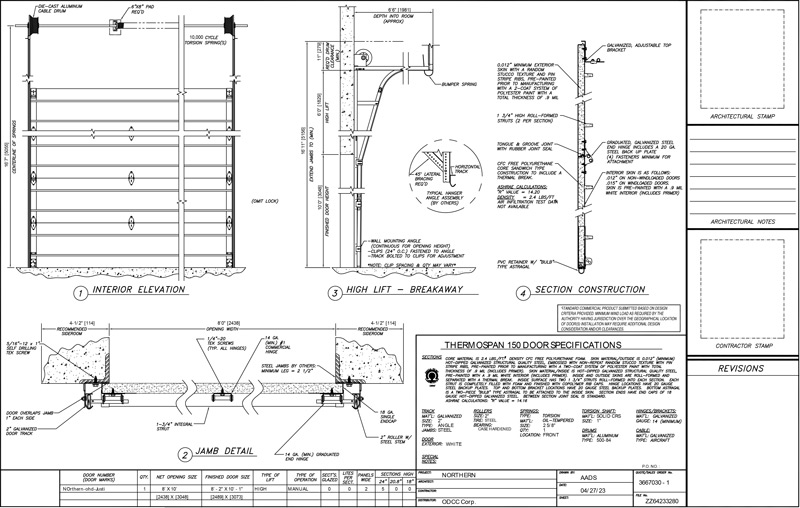

High-Lift Overhead Sectional Door

On the new dock door, we installed a new 8’x10′ high-lift Overhead Sectional Door to match the other dock doors. This overhead sectional door is insulated and has a R-value of 14.16. Additionally, the spring has an estimated 10,000 spring cycle lifespan.

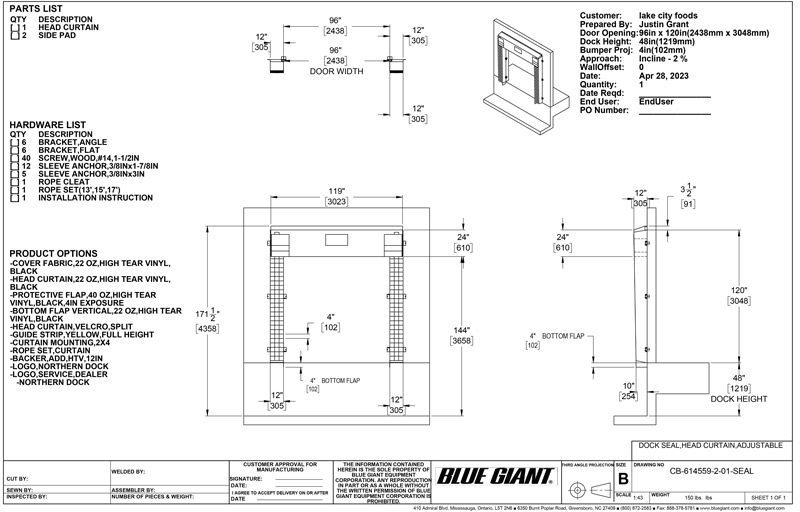

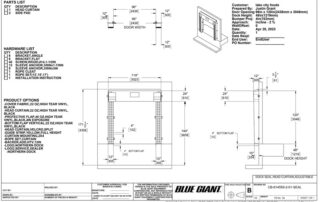

Head Curtain Dock Seal

Finally, to create a tight seal around trailers, we added a Blue Giant Head Curtain Dock Seal. The two resilient foam side pads act as a cushion between the trailer and the building while the full-width weighted head curtain conforms to the trailer top. While the sloped head curtain supports proper drainage to prevent water build-up.