Northern Dock Systems develops custom-tailored solutions to overcome unique challenges.

Company: Winners, TJX

Province: Alberta

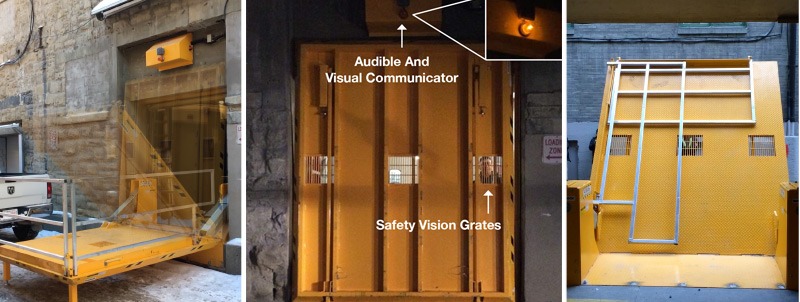

Allowing Safe And Efficient Offloading

Northern Dock Systems has successfully completed a custom drawbridge loading platform in Alberta for Winners (TJX).

Challenge

Northern Dock Systems was approached by the TJX construction team with a unique challenge that their suppliers couldn’t solve: Install a loading platform in a narrow downtown alley where delivery trucks could not back up to the dock. Previously the store had utilized a cable-driven drop platform but the cable had snapped previously, creating an extremely dangerous situation as the platform crashed to the ground.

Conditions

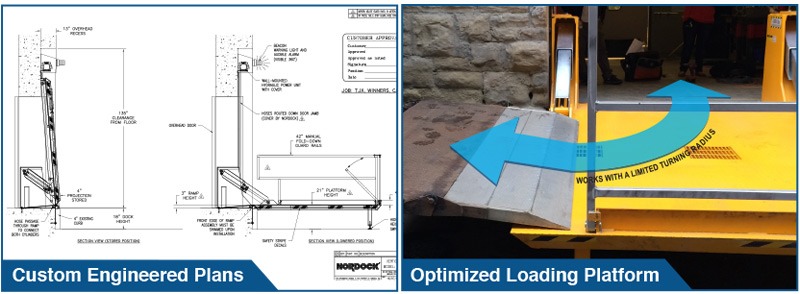

The store is in a Calgary historic area so no permanent equipment could be installed in the alleyway causing an obstruction. The loading platform needed to work with the existing store design and could not create any major construction or disruption.

Safety for store staff, delivery personnel and any pedestrians is always an important factor for TJX as a company. Additionally the loading platform needed to stand up to daily use and in all weather conditions in Calgary.

Solution

After meeting with TJX, Northern Dock Systems gained an in-depth understanding of the site conditions and store operations. A design was then developed using TJX’s unique parameters to satisfy all operational and physical requirements of the project.

Working closely with the TJX logistics team first, we determined that the delivery truck design and style that requires access would be equipped with a lift gate. We were then able to consult with the TJX construction team on certain considerations and performance criteria that need to be met and altered the design into the final specification and design of the product.

The installation process was complete in one day including electrical and mechanical work.

Operation and Features

The delivery truck parks alongside the building, perpendicular to the receiving area, and at an assigned mark.

The store staff lifts an interior door which exposes the vertically stored platform. The platform can only be operated while the door is fully open.

The store staff looks through grates in the floor of the platform to communicate with the delivery driver to be certain that the area is secure and safe.

The store staff presses the “lower” button which initiates an audible sounder with visual flashing light to warn anyone outside that the platform is in motion. The button is within reach of the communication ports for the operator, and must be held to have continuous operation. This assures safe operation for the full lowering of the platform.

When the platform is in the full-down position, a green indicator light on the operations panel will illuminate, signaling the store staff that the platform is safe to walk on. When the button is released, the audible sounder stops while the flashing light remains on.

The store staff can now lift the safety barriers at the non-loading sides of the platform.

The delivery driver can now open and extend the lift gate and raise it to begin to the unloading process. When the lift platform drops to the loading platform, there is 12” of lip purchase, allowing for safe transferal of the load on the pallet jack. The large platform provides for ample turning room with safety rails at the sides.

When the unloading process is complete, the delivery truck driver stores the lift gate, the store staff drops and secures the safety gates (the platform will not operate if they are not stored and secured), and the store presses and holds the “raise” button. The audible sounder will sound as the platform is lifted to the fully stored position. While the platform is in motion and stored, a red indicator light on the control panel will be illuminated to communicated that the platform should not be used.

When the loading platform is stored, the interior overhead door can be closed and secured.