Jump to: Information | Photos | Videos | Customers | Specifications | Customizations | Warranty

Vertical Storing Dock Levelers

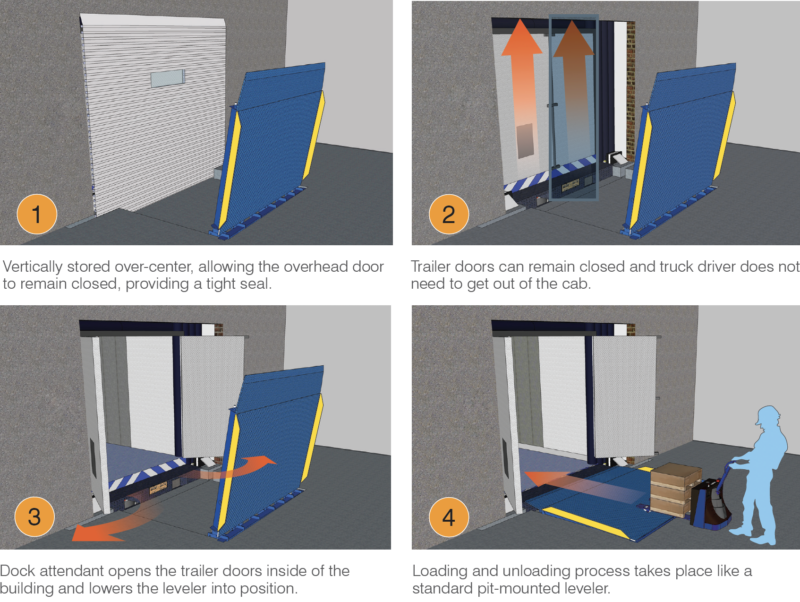

The vertical storing dock leveler is the perfect solution for facilities that must maintain strict temperature control. Stored in the vertical position inside the building, overhead doors close completely to the pit floor, preventing energy loss, debris entry and improved security while maintaining a clean, energy-efficient environment.

✓ Environmental Control: Closed and tightly sealed overhead doors maintain environmental control by keeping pests and debris outside. Preserve climate control inside the facility and ensures product quality from raw materials to finished goods.

✓ Enhanced Cleanliness: The EasyClean feature simplifies cleaning and maintenance with a streamlined frame layout. The powder coat finish prevents rust and corrosion, keeping the facility cleaner for longer.

✓ Safety and Durability: SoftPark provides protective cushioning for the deck cylinder, minimizing wear and tear on the facility floor. The hydraulic velocity fuse limits platform free-fall, and the power pack ensures longevity and serviceability.

✓ Advanced Technology Integration: IntelliTilt uses a precision-based inclinometer to protect and communicate deck position, while SmartFloat sensor technology keeps the lip in constant contact with the truck bed.

Information

Significant Energy Savings for the Cold Storage Industry

Installing the right dock leveler is imperative for the cold storage industry. Cold storage dock levelers effectively seal the fourth side of the pit during loading operations to maximize energy efficiency while preventing insects, pests, dust and white light infiltration—key food and personnel safety hazards auditors check most.

Vertical storing dock levelers allow for overhead doors to close completely to the pit floor, preventing energy loss, debris entry and improved security while maintaining a clean, energy-efficient environment.

Cold Storage

Maintaining cold chain integrity during the loading and unloading process is crucial. It’s essential to avoid exposure to the outside atmosphere while preserving climate control inside the facility. This helps eliminate internal temperature fluctuations and ensures product quality from the arrival of raw materials to the shipping of finished goods.

Cleanliness from Contaminants

To maintain environmental control, overhead doors should remain closed and tightly sealed, keeping pests and debris outside. The pit floor should be easily washable and sanitizable to ensure the highest level of cleanliness. A powder coat finish will prevent rust or corrosion, keeping the facility cleaner for longer.

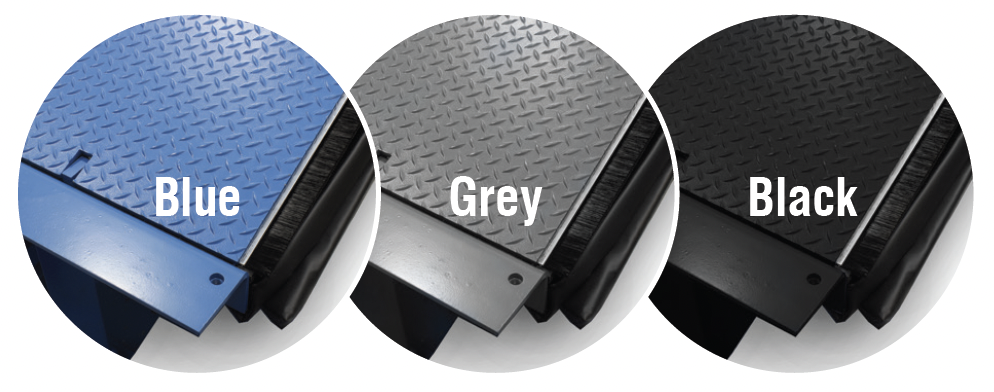

Rust-Resistant Powder Coat

The only hydraulic dock leveler in North America to feature a powder coat finish as a standard. This Blue Giant’s powder coat finish provides a long-lasting and rust-resistant finish and colour. It is available in blue, black, grey and yellow.

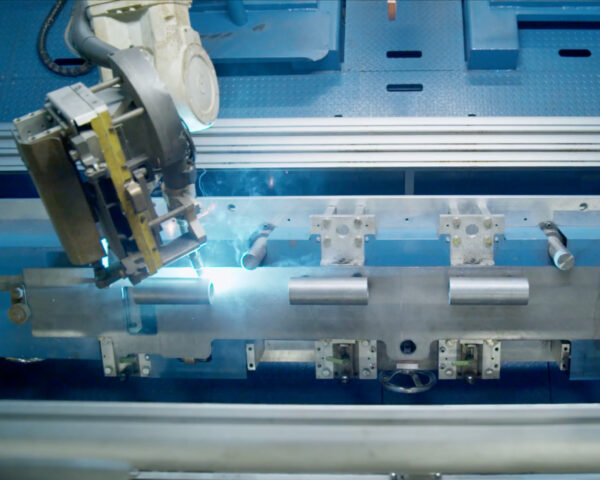

Consistent Quality and Strength

The Blue Giant’s state-of-the-art robotic welding ensures structural integrity and uniform quality. Get peace of mind knowing that every weld has the same quality and care put into it

Vertical Dock Operation for Cold Storage Facilities

Blue Genius Connect and Connect Plus

Control Panels

Easy to Operate

Food and Pharmaceutical Safe

The NEMA4X (moisture and corrosion resistant) push-button control station with the largest LCD screen on the market enables sequenced deck and lip operation.

Maximize unit versatility with optional independent lip control that drastically reduces cycle time and energy use, perfect for below-level or end-loading applications.

Upgrade to a Blue Genius Connect control panel to integrate with your docks, trailer restraints, doors and/or dock lights.

Photos

Videos

Vertical Storing Dock Leveler: Drive-Through ApplicationThe vertical storing dock leveler is the perfect solution for facilities that must maintain strict temperature control. Stored in the vertical position inside the building, overhead doors close completely to the pit floor, preventing energy loss, debris entry and improved security while maintaining a clean, energy efficient environment. |

Dock ManufacturingBlue Giant is the global leader in the development, manufacture and distribution of loading dock systems and material handling equipment. The new Headquarters is an impressive state-of-the-art manufacturing facility with robotic welding and standard powder coating. |

Vertical Storing Dock Leveler Pre-Installation InstructionsThis video outlines the steps for preparing your loading bay area for the installation of the Blue Giant Vertical Storing Dock Leveler. |

Storing Dock Leveler Installation InstructionsThis video outlines the steps for preparing your loading bay area for the installation of the Blue Giant Vertical Storing Dock Leveler. |

Specifications

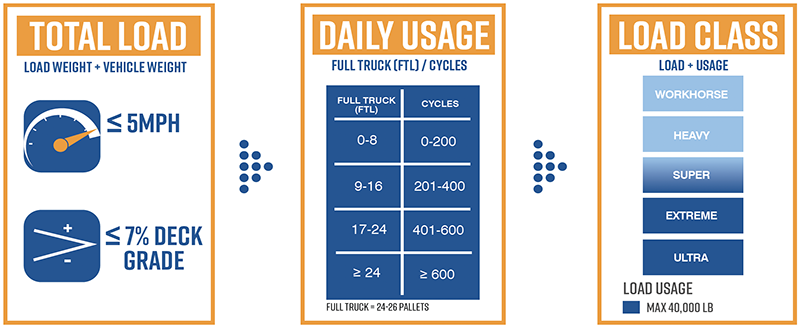

| Load Class Available | Heavy, Super or Extreme |

| Load Usage | Up to 33,000 LB |

| Nominal Size | 6' x 6' to 7' x 8' |

| Lip Length | 18", 20" |

| Standard Pit Depth | Front: 12.5" (318mm) Rear: 12" (305mm) |

| Optional Pit Depth | Front: 15.5" (394mm) Rear : 15" (381mm) |

Customizations

- Lip Length 18" (457 mm) or 20" (508 mm)

- Draft pad

- Biodegradable oil, Arctic oil

- Blue Genius Touch Control Panel for independent lip control to decrease cycle and energy use.

- Upgrade control panel to intergrate with trailer restraints, doors and/or dock lights.

- Finish Options: Anti-slip PowderCoat, enriched zinc PowderCoat or hot dipped galvanizing.

- Colour Options: Blue, grey or black

- Trailer restraint systems or wheel chocks.

- Fall-Stop safety barrier gates.

- Brush weather seals.

- Steel face dock bumpers.

- Dock lights.