Project Overview

Precision Electronics recently relocated to a new building in Toronto, but they found that their new location did not have a loading dock. Although they don’t ship products frequently when they do, they use skids, so they needed a loading solution that was cost-efficient and safe. They wanted to avoid the expense and hassle of digging a decline approach pit.

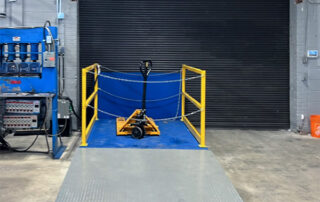

To find a solution, they contacted Northern Dock Systems, who recommended a Blue Giant Dock Lift as the best option for their needs. The Dock Lift is an elevating platform that can safely and efficiently take pallets from the ground to 4′ truck beds. Additionally, a 10′ long floor ramp was added to create a gentle slope onto the Dock Lift, making it easier and safer to manually push the skids onto it.

Once the skids were loaded onto the lift table, they could easily be controlled with a hand-held push button. The top of the deck and lip have an anti-slip powder coat to prevent slips, falls and accidents. Along with the OSHA-compliant guard rails.

To ensure safety, a beacon light and safety accordion skirts were installed since many people would be using the area. Bollards were also added outside of the drive-in door to prevent trucks from accidentally backing into the new lift table and causing damage.

Thanks to these improvements, Precision Electronics can now easily and safely load and unload their shipments on skids at their new location without having to undertake an expensive construction project.