Project Overview

The Old Unsafe Dock Board

LKM Parts Manufacturing in Aurora had no loading dock and was using a dock board that was unsafe. In addition, it was causing a lot of unnecessary strain on the workers’ backs to lift and place the dock board.

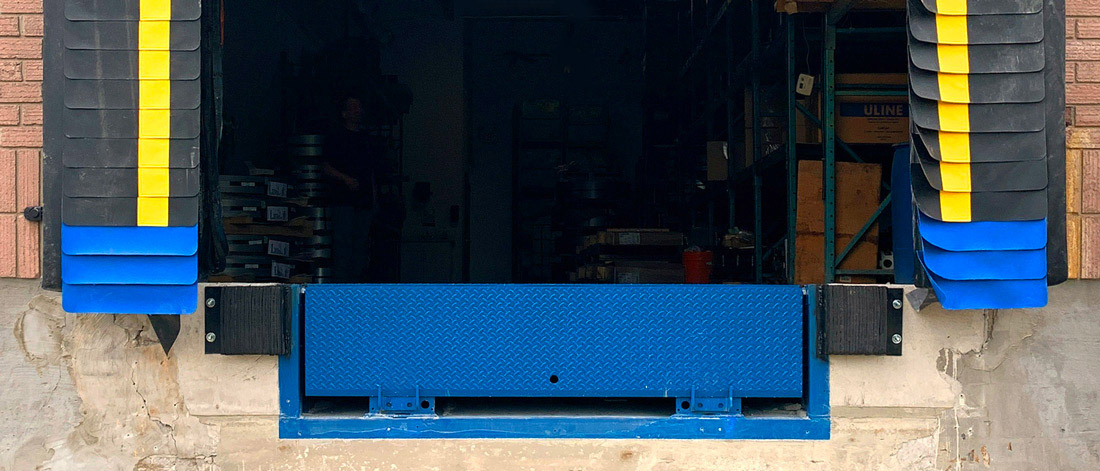

New Dock Pit and Blue Giant Hydraulic Dock Leveler

Northern Dock Systems excavated and poured new concrete for the new dock pit. Next, we installed a Blue Giant hydraulic dock leveler in the newly constructed dock pit. As a result, this hydraulic dock will make the loading dock much safer. Staff can easily operate the hydraulic dock with a push of a button, rather than risk injury by lifting a heavy dock board.

Furthermore, the fixed rear design allows the deck to flex up to 4″ when under load to ensure full-width contact between the lip and the truck bed. Also, this rear hinge design provides a smooth transition for 3 or 4 wheel forklifts.

In addition, the NEMA4X push-button control station is moisture and corrosion-resistant, making it safe for this manufacturing plant.

Sealing Up Energy-Savings and Protecting the Building

Finally, we finished off this new dock with an L-pad foam pad dock shelter to create a tight seal around the trailer for energy savings. Along with 4″ dock bumpers to protect the new dock leveler and dock shelter.

Rust-Resistant Powder Coat

The only hydraulic dock leveler in North America to feature a powder coat finish as a standard. This Blue Giant’s powder coat finish provides a long-lasting and rust-resistant finish and colour. It is available in blue, black, grey and yellow.

Consistent Quality and Strength

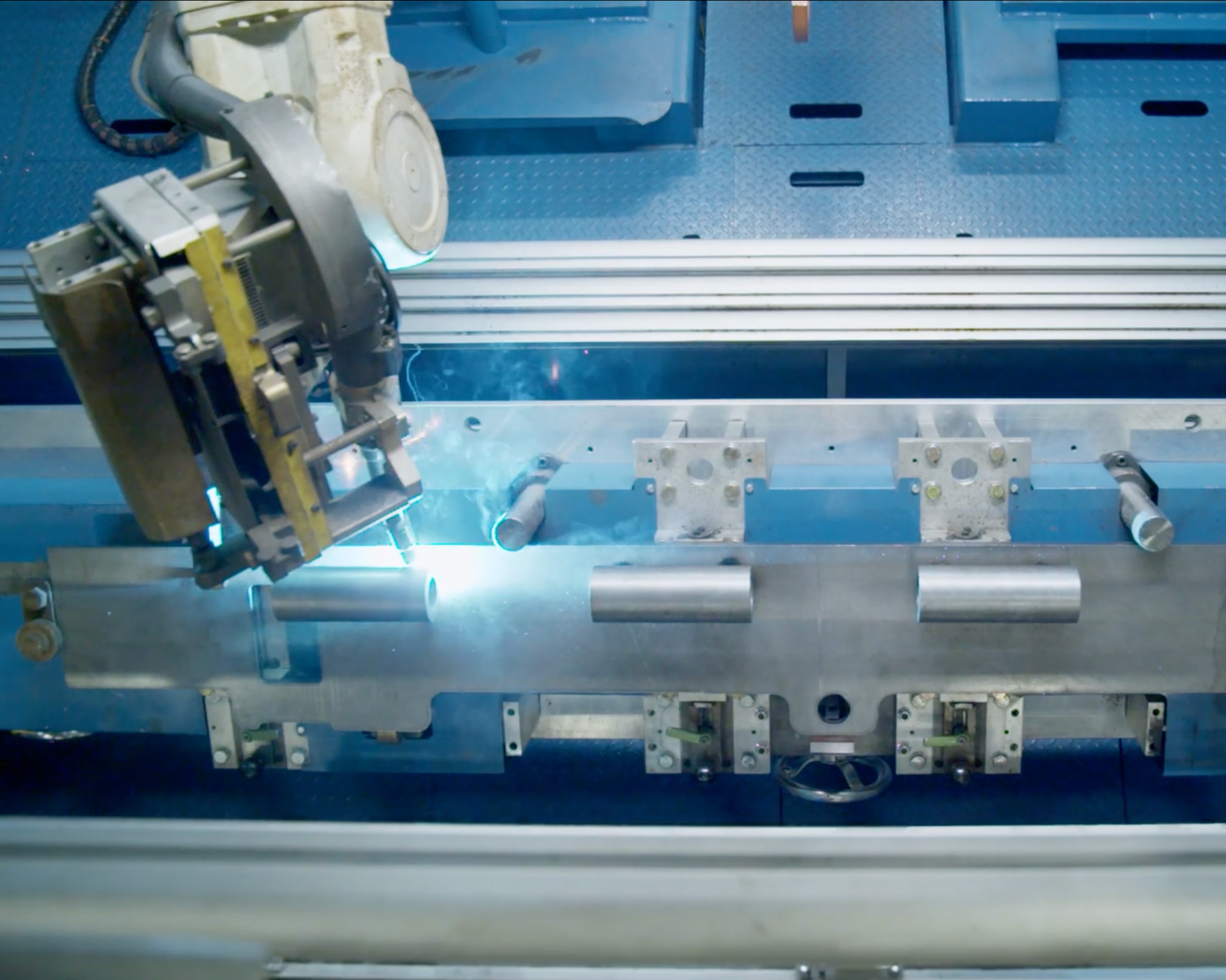

The Blue Giant’s state-of-the-art robotic welding ensures structural integrity and uniform quality. Get peace of mind knowing that every weld has the same quality and care put into it.