Before (Right) & After (Left)

Four year old dock leveler already dishing in the middle

Project Overview

When Kraft Heinz Canada constructed a new warehouse in Halton Hills four years ago they went with an inferior competitor’s dock leveler. However, after just four years these docks had already started to fail structurally.

This was due to a low-quality dock being used at 24/7 facility that had heavy use. Additionally, the dock was not configured for three-wheeled forklifts, which caused major dishing in the center of the dock plates. As a result, due to safety concerns, they decommissioned the dock from use until it could be replaced.

Contacting the Experts for a Heavy-Duty Dock Leveler

So, they contacted Northern Dock Systems to replace their docks with heavy-duty dock levelers that could keep up with their facility. First, our installers had to remove the existing docks and pour-in pans.

Hydraulic Docks Ready for Installation

Suitable for Three-Wheeled Forkifts

Next, our team installed new higher-capacity Blue Giant Super hydraulic dock levelers. The Super model dock has 6″ of beam spacing, compared to the traditional 8″, for more support for three-wheeled forklifts.

6″ Beam Spacing

Suitable for three-wheeled forklifts

Rust-Resistant and Consistent Quality

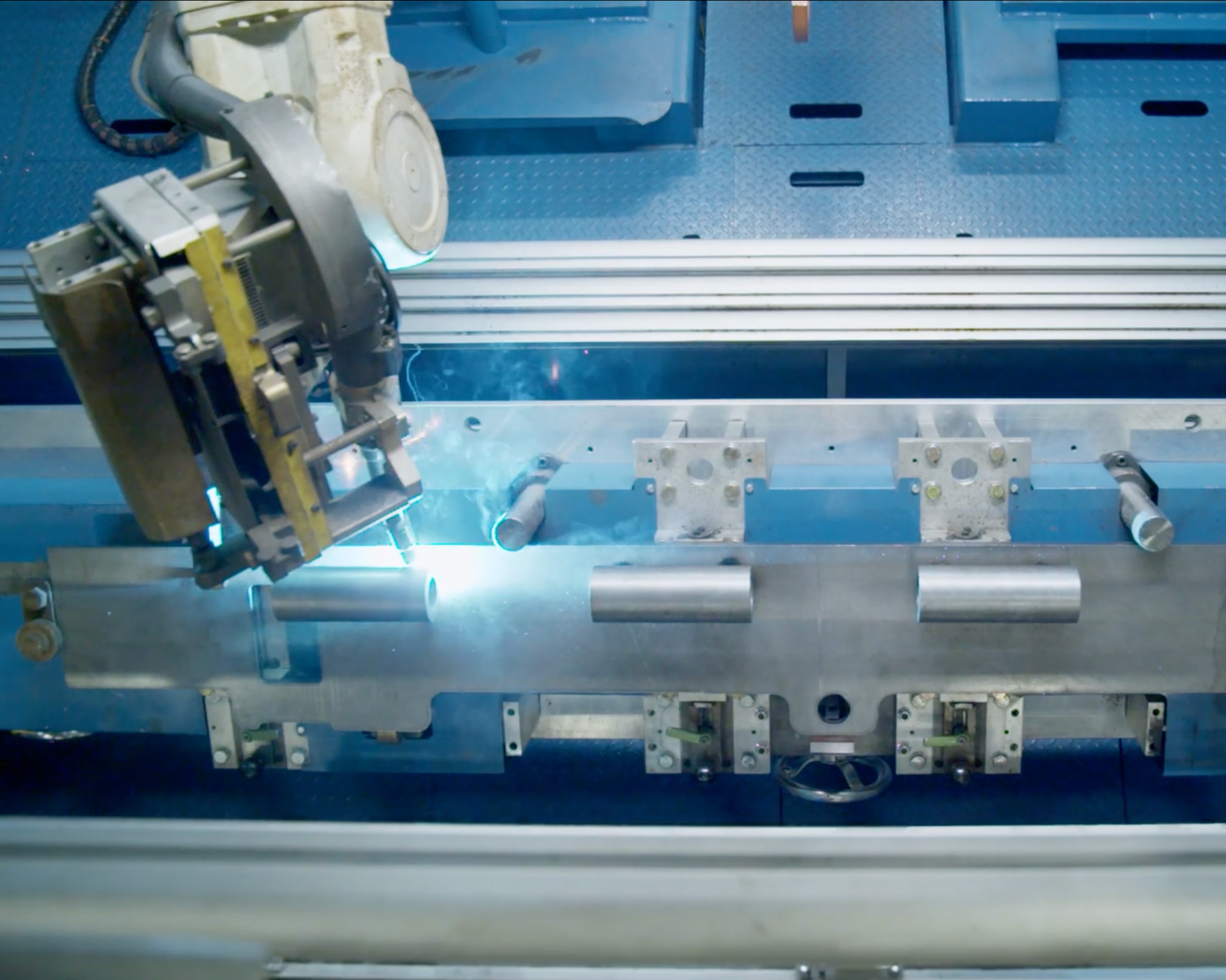

Furthermore, the rust-resistant powder coating will provide a long-lasting finish. While robotic welding will provide structural integrity and consistent quality across all the welds on all the docks. This is why these Blue Giant hydraulic dock levelers boast a 10-year structural warranty because they know their equipment will last.

Robotic Welding

Preventing Food Contamination

Due to this being a food facility, our team made sure to tarp off the work area for each dock installed. As a result, employees were not affected by the welding light, welding fumes, dust and debris. In addition, we protected their food product from contamination and birds.

Tarped Off Work Area

No Additional Training Needed

In order to keep the operation the same, our installers tied the dock levelers in the existing combination control panels. As a result, the 200 employees at this facility did not need any new training to work the new docks.

Reusing Existing Control Panels

Protect with Steel Face Dock Bumpers

Finally, in order to protect the new docks from damage to the backing-up trucks install new steel face dock bumpers with risers. Steel face dock bumpers are the #1 defence to protect your equipment and building from potential truck damage. Additionally, the risers make sure that the bumpers are in the correct position for these incoming trailers.

Steel Face Dock Bumpers

Another Happy and Returning Customer

Kraft Heinz Canada originally purchased 50 dock levelers to replace their failing ones. However, after the installation, they were so happy with our service and the Blue Giant docks that they immediately purchased 25 more dock levelers to replace the remaining