High-Speed Overhead Door Operators

Jump to: Information | Activation | Photos | Videos | Customers | Models | Compare | Customizations | Warranty | Specifications

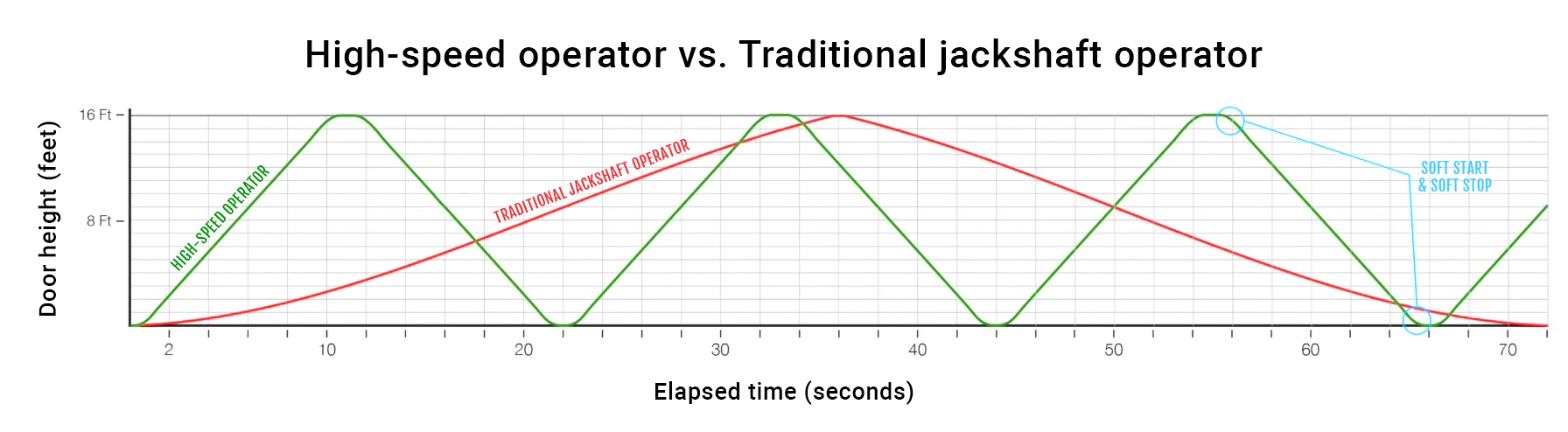

High-Speed Overhead Door Operator vs. Traditional Operator

Upgrade to a high-speed overhead door operator to increase operational efficiency and throughput. This video demonstrates a direct speed comparison between a traditional jackshaft operator and our high-speed springless Safedrive operator.

| Turn almost any overhead door into a high-speed door with the springless Safedrive high-speed operator. |

✓ Energy efficiency: High operating speeds mean energy-efficient operation, minimizing outside air infiltration during operation.

✓ Versatile applications: Convert almost any balanced or unbalanced overhead door into a high-speed door.

✓ Better operational efficiency: Increase throughput with high-speed doors.

✓ Minimize or eliminate maintenance: Minimize or eliminate maintenance costs (model dependent) and enhance reliability in daily operations.

Information

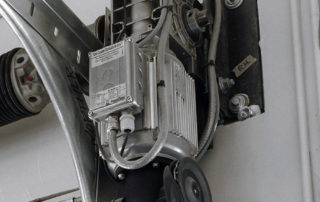

A Maintenance-Free High-Speed Springless Safedrive Operator

The high-speed springless Safedrive operator is maintenance-free, self-monitoring and operates silently. Its incredibly fast opening speeds of up to 24″/second is energy-efficient and helps to increase operational efficiency, throughput and worker productivity, while its springless design eradicates costly spring repairs and replacements. In addition, this high-speed operator reduces energy loss and prevents air exchange from slow operators that allow heat and/or cooled indoor air to escape out the door.

Ideal Applications for High-Speed Overhead Door Operators

High-speed overhead door operators are used in a variety of commercial and industrial applications. They are best suited for car wash/automotive dealerships and food storage/manufacturing facilities. The Safedrive high-speed operator is designed to operate on numerous types of overhead doors including: aluminum polycarbonate, aluminum Lexan, rolling steel, rolling grilles, shutter, rubber roll-up, fabric roll-up, sectional, horizontal single-leaf, and more.

Activation Method

The most important aspect of any door project is deciding on your activation method to:

✓ Prevent the door from being hit

✓ Prevent the door from hitting people

✓ Extend the life of the door

✓ Improve productivity

✓ Decrease downtime and maintenance

✓ Save energy

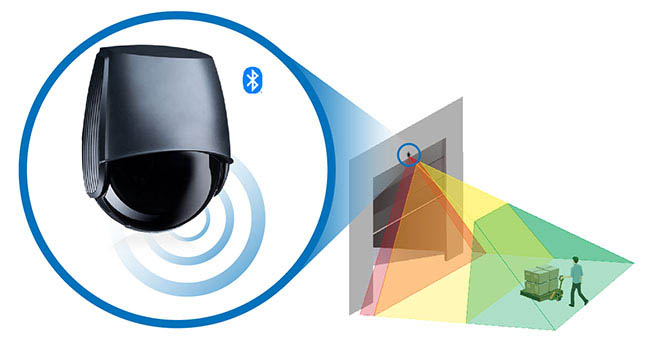

Motion, presence and safety all in one. These sensors can be set to open for only incoming pedestrian or forklift traffic. Speed up workflows by installing or retrofitting dock, industrial, pedestrian and entrance doors with automatic motion sensors. View »

Prevent cross-contamination by never having to touch a door to open it. Install or retrofit dock, industrial and pedestrian doors with touchless wave sensors. View »

Photos

Videos

High-speed performance door system with springless Safedrive operatorSee the full high-speed performance door solution we've implemented at an automotive dealership. |

Custom blackout high-speed automotive door with springless Safedrive operatorNorthern Dock Systems designed custom blackout high-speed doors for a local automotive dealership. |

Increase efficiency: up to 3x faster cyclingAfter installing a high-speed operator in a narrow space, our customers are able to increase their throughput. |

High-speed operator vs. jackshaft operatorWatch a high-speed operator in action as it outperforms a traditional jackshaft operator in speed. |

Models

|

High-Speed Springless Safedrive Overhead Door OperatorThe high-speed springless Safedrive operator is maintenance-free, self-monitoring and operates silently. Its incredibly fast opening speeds of up to 24"/second is energy-efficient and helps to increase operational efficiency, throughput and worker productivity. |

Model Comparison Chart

| Springless Safedrive Operator | ||

| Opening speed | Up to 24"/sec | |

| Power configuration | 230V, 1 ph Transformers available for other voltages |

|

| Quiet operation | ||

| Built-in cycle counter | ||

Customizations

High-Speed Springless Safedrive Operator

- Auxiliary crank operation.

Warranty

- 1 year limited.

Specifications

- Anti-back drive reducer standard.

- Safedrive limits set at ground level.

- Pre-wired control panel with easy setup instructions.

- Status indication screen on control panel.

- Manufactured to quality standard DIN EN ISO 9001, ensuring trouble free installation and operation.

- Anti-Backdrive is maintenance-free and provides safety for reducer failure and operates independently of speed/direction.

- UL approved.