Jump to: Information | Activation | Photos | Customers | Models | Compare | Customizations | Warranty

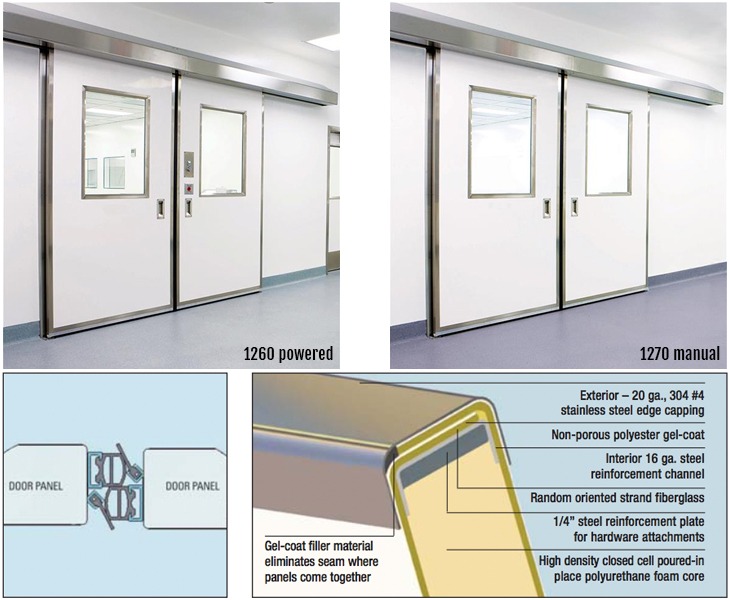

✓ Exceptionally clean: Totally seamless polyester gel-coat finish with non-porous, non-shedding, and non-absorptive panel surface.

✓ Intelligent: Incorporates state-of-the-art direct drive technology using a self-adjusting microprocessor controls and on-board diagnostics.

✓ Durability: Exclusive all-stainless steel (no aluminum or other soft metals) heavy-duty rail and trolley assembly with 16 ga. stainless steel side frames and floor hardware.

✓ Airtight seal: Continuous three-sided non-marking vinyl gasket, interlocking centre seal and bottom sweep gasket ensures the tightest seal.

✓ Maximum security: A variety of electronic and mechanical locking options to meet strict FDA requirements.

✓ Performance and reliability: Cleanseal doors have proven to be the benchmark for maintaining the strictest clean environment production areas worldwide.

Information

Setting a New Standard for Airtight Cleanrooms

Cleanseal’s revolutionary totally seamless molded fiberglass bi-part sliding door system is designed, engineered and precision manufactured with over 20 years of experience partnering with leading pharmaceutical companies and architects. Using cutting-edge technology and exacting criteria for quality, these bi-part sliding doors have surpassed market demands and exceed cGMP, FDA and EMEA requirements.

The powered and manual models come with a unique double interlocking centre seal to prevent panel separation under positive or negative pressures. Cleanseal’s exclusive process utilizing polyester gel-coat offers a fiberglass door that is truly seamless. Cleanseal fiberglass doors are built to a higher standard so they withstand the harshest conditions and still look great year after year.

Powered Bi-Part Sliding Fiberglass Door

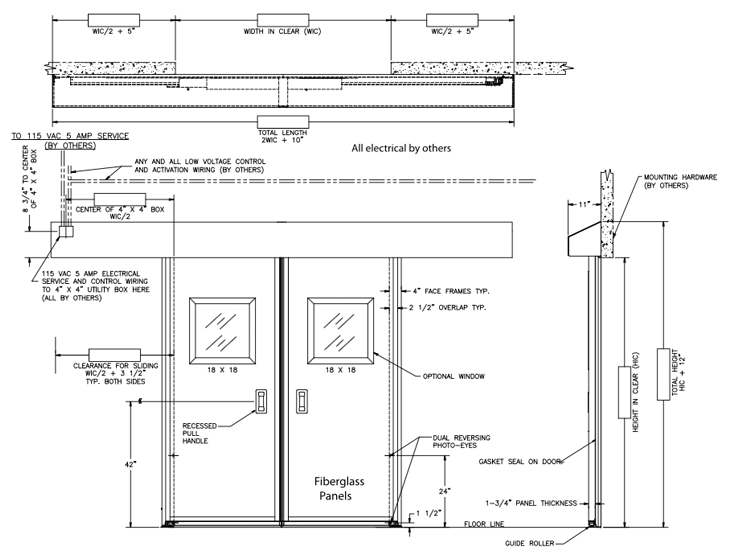

The 1260 model is powered using a gearless AC asynchronous motor that continuously maintains peak performance. Its state-of-the-art onboard self-adjusting microprocessor control system eliminates external controls and provides infinite adjustability and exceptional reliability for door sizes up to 10’x10′. Furthermore, in case of power failure, these Cleanseal powered doors can be manually operated at any time.

Additional Features

- Standard push plate to open with a time delay to close.

- Standard circuitry allows the door to reverse upon obstruction by monitoring both directions of door travel.

- Standard dual side frame mounted reversing photoeyes.

Activation Method

The most important aspect of any door project is deciding on your activation method to:

✓ Prevent the door from being hit

✓ Prevent the door from hitting people

✓ Extend the life of the door

✓ Improve productivity

✓ Decrease downtime and maintenance

✓ Save energy

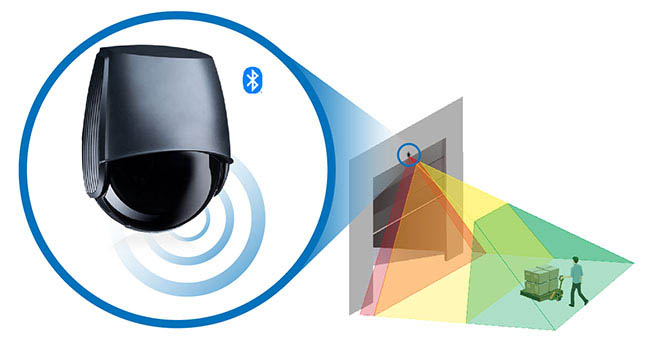

Motion, presence and safety all in one. These sensors can be set to open for only incoming pedestrian or forklift traffic. Speed up workflows by installing or retrofitting dock, industrial, pedestrian and entrance doors with automatic motion sensors. View »

Prevent cross-contamination by never having to touch a door to open it. Install or retrofit dock, industrial and pedestrian doors with touchless wave sensors. View »

Photos

Models

|

Cleanseal 1260 Powered Bi-Part Sliding Door for Sterile EnvironmentsCleanseal's model 1260 bi-part sliding seamless molded fiberglass door uses a gearless AC asynchronous motor that continuously maintains peak performance by utilizing an onboard self-adjusting microprocessor control system. This automatic bi-part sliding door fits door sizes up to 10'x10'. |

|

Cleanseal 1270 Manual Bi-Part Sliding Door for Sterile EnvironmentsThe 1270 manual bi-part sliding seamless molded fiberglass door has an automatic close with "hold-open", available for door sizes up to 8'x8'. |

Model Comparison Chart

| Cleanseal 1260 powered | Cleanseal 1270 manual | |

| Max. door opening | 10'x10' | 8'x8' |

| Type | Powered | Manual |

| Panel construction | ||

| Performance | Gearless AC asynchronous motor continuously maintains peak performance using an onboard, self-adjusting microprocessor control system. Complete system is programmable from floor level without removing the shrouds. | Automatic close with "hold-open" |

| Header, rail and side frame construction | ||

| Standard colour | ||

Customizations

Cleanseal 1260 powered

- Vision panel with standard sloped frame.

- CleanView flush vision panel.

- 304 or 316 #4 stainless steel clad panel.

- Custom color (consult factory).

- Mechanical canebolt lock in door panel.

Cleanseal 1270 manual

- Activation devices mounted in door panel.

- Electronic solenoid lock in header.

- Touchless activation switches.

- Custom designed interlocking system.

- Actuators: a variety of activation devices are available upon request.

- Pre-announce to close kit (light, alarm or combo).

Warranty

• 1 year limited.