It can be difficult to decide whether you need a mechanical or hydraulic dock leveler for your facility. You might be tempted to look at a mechanical dock leveler in order to save on new equipment costs.

However, the original money you save may not be worth it. The continuous issues and service calls that mechanical dock levelers need will cause higher maintenance costs when compared to a hydraulic dock.

Mechanical Dock Maintenance and Safety Issues

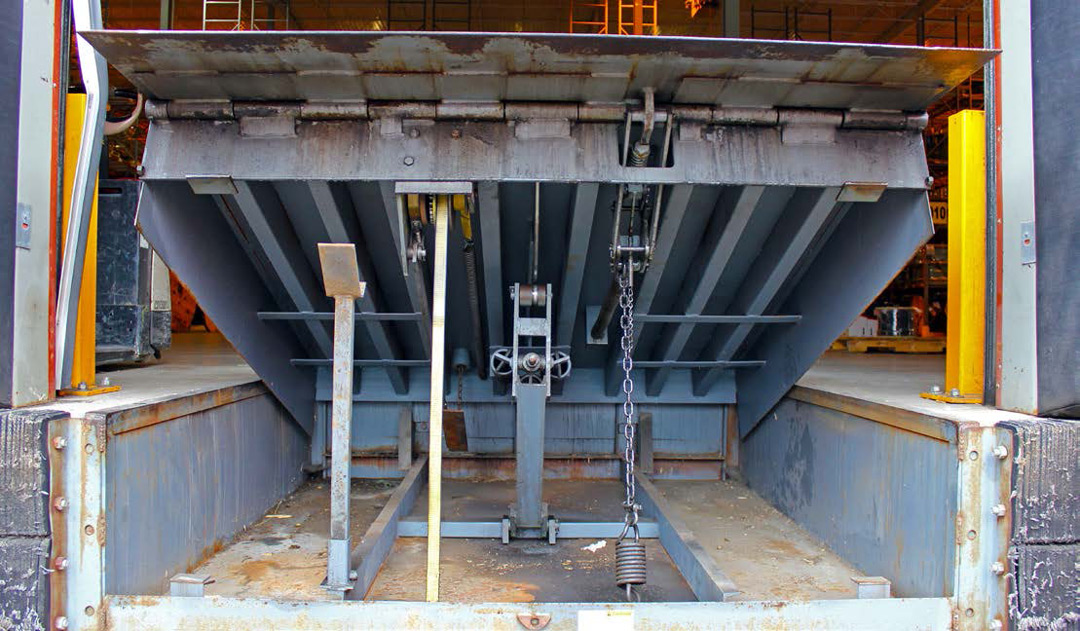

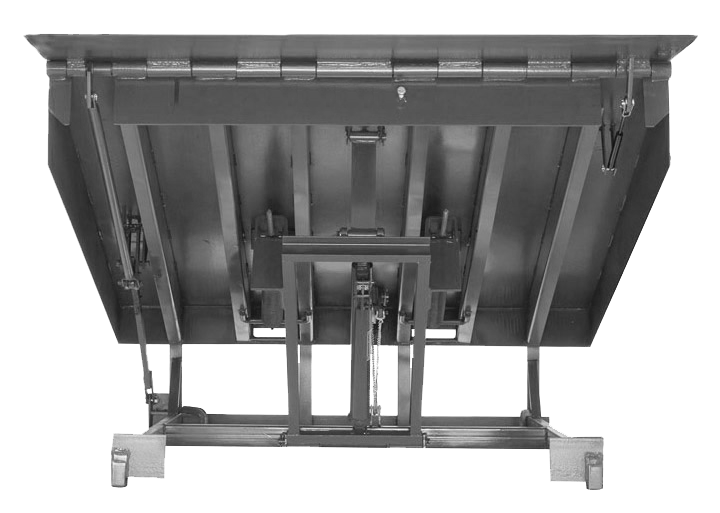

Springs Under High-Tension

The spring on a mechanical dock leveler is always under high tension in order to lift the heavy dock and 300 lb lip. As a result, the dock:

- Requires continuous maintenance to keep springs balanced.

- The springs and hold-down mechanisms are common causes for service calls.

- Delivery times for specific model parts could lead to days of downtime.

- There is a chance of injury if an employee tries to physically engage the dock when it’s not working properly.

Furthermore, if the spring tension isn’t correct, the lip won’t extend. This could lead to:

- A chance of injury when an employee tries to extract the 300 lb lip by hand.

- The Ministry of Labour could get involved.

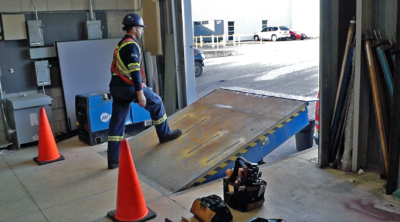

Workers Need to Bend Over to Engage the Dock

Employees need to bend over and pull the chain to engage the dock. As a result, there is:

- A chance of injury when trying to engage dock.

- The Ministry of Labour could get involved.

Risk of Injury When Walking Down a Mechanical Dock

Employees need to walk down mechanical dock levelers after use. As a result, workers could slip, fall or injure themselves if the dock plate is wet or icy. This is why the Ministry of Labour could get involved.

Trailer Tip-Over and Creep

There is no way to interlock the dock with the restraint. Consequently, the dock could be engaged before the trailer is properly secured. As result, the trailer could tip over or creep away from the dock. Which could lead to an injury that the employer is liable for.

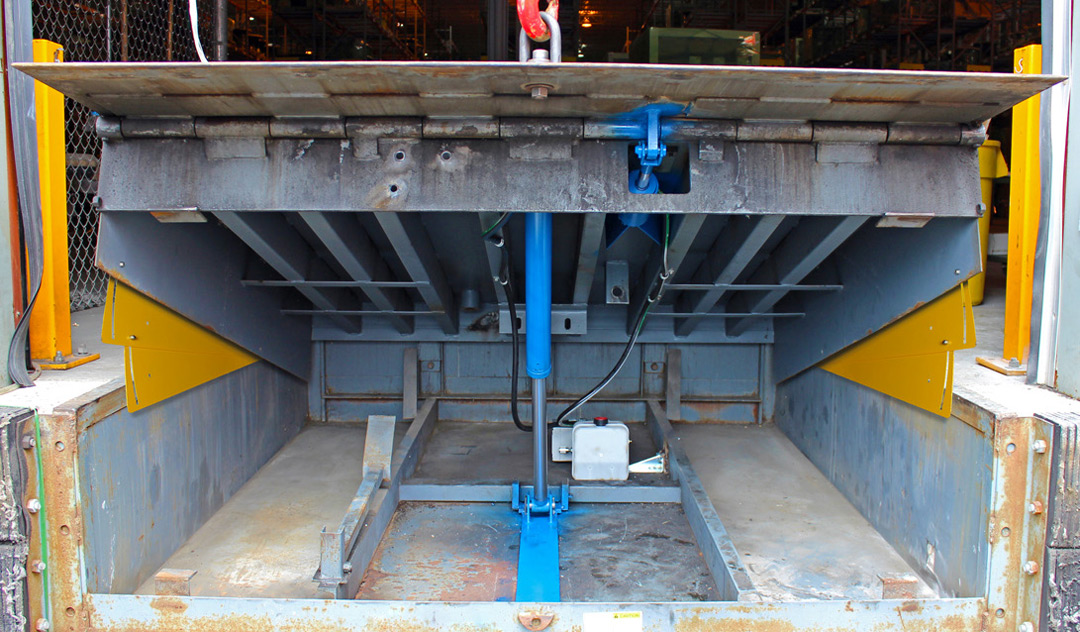

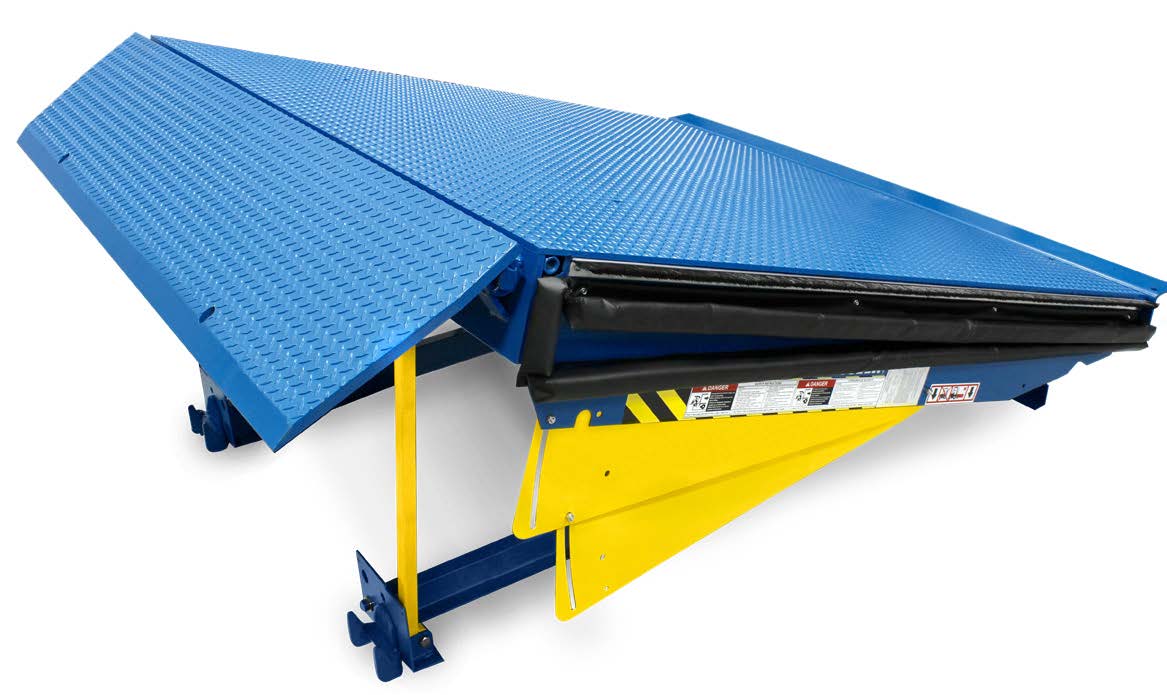

Hydraulic Dock Leveler Low Maintenance Benefits

No Springs, No Issues

Hydraulic dock levelers have no springs, hold-down mechanisms or other high wearable parts that mechanical dock levelers have. As a result, hydraulic dock levelers require:

- Less maintenance

- Lower cost of ownership

- Lasts longer

- Increases safety

Low Maintenance

Safer Operation with Push Button Controls

Push buttons for safe control during the operation of the hydraulic dock leveler.

- Less opportunity for injury since employees don’t have to bend over and pull chain.

- Improves safety.

Interlock with Restraints

Hydraulic docks can interlock with trailer restraints to make sure that the dock can’t be activated until the restraint is safely engaged with the trailer.

- Improves safety.

- Prevents trailer tip overs and trailer creep.

Convert Mechanical Dock Levelers to Hydraulic