Project Overview

In this manufacturing plant in Mississauga, the existing door was slow which resulted in energy loss. Additionally, the employees were complaining of the cold working conditions because the door was opened for too long.

In order to counteract the slow door, strip curtains were added. However, these strip curtains were continuously being damaged and need to be replaced often, which was costly. Moreover, these strip curtains were getting dirty causing low visibility for forklift traffic. Furthermore, the open procedure required for employees to get off the forklift and press the open button exit door then close the door manually or leave it open until they come back in.

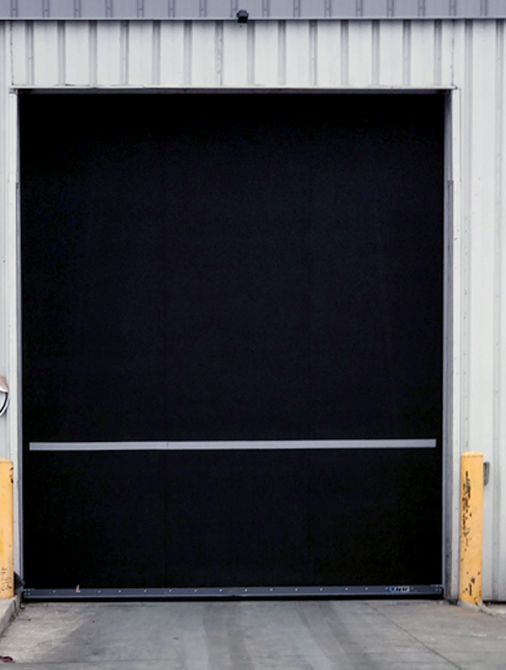

They contacted Northern Dock Systems to supply and install a high-speed heavy duty high cycle rubber door with a timer to close, which would allow for the forklift traffic to exit through the door and then the door shut automatically. Furthermore, the Falcon motion sensors on both sides of the opening allow forklifts to just drive into view and the door will open and close automatically.

This solution eliminated the dangerous strip curtains which could cause an accident. Moreover, it provided energy savings and created a warmer and more comfortable work environment as the door is operating faster and is spending less time open. Also, this springless rubber door is quick and easy reset if ever hit with knock away bottom bar, saving time and money on costly repairs.