Project Overview

A warehouse in Calgary was unable to secure their building as the lip on their mechanical dock leveler was stuck in the up position.

Quick Response Times

They reached out to Northern Dock Systems’ 24/7 emergency service team to repair their mechanical dock leveler before closing. As a result, our local dispatch team was able to schedule a technician to their location within one and half hours.

First-Time Fix

When our technician arrived at the Calgary warehouse, he discovered that the mechanical dock’s lip was not retracting.

After his inspection, he discovered that the root cause was the lip spring. After a quick re-adjustment of the lip spring, the lip was able to retract and the building was secured.

In under 2 hours, from the time the service call was place to the time the technician repaired the dock, we were able to meet our customers request to secure the building before closing.

Recommendations to Prevent Future Service Calls

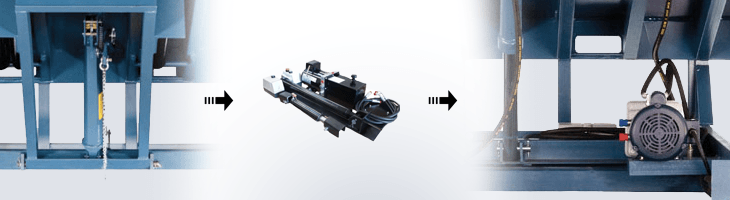

In order to prevent future emergency service calls, our technician recommended that this warehouse upgrade its dock with a hydraulic conversion kit.

Springs and hold-down mechanisms are the number one reason for service calls on mechanical dock levelers. These springs need to have continuous high-tension in order to lift the 300 lb. dock lip. As a result of this high tension, the springs are more likely to fail.

By removing the springs and hold-down mechanisms with a springless and cost-effective hydraulic conversion kit, this Calgary warehouse could save up to 91% on maintenance costs over 10 years.

Emergency repair

First-time fix

Improve safety

Operational efficiency

Workplace productivity