Project Overview

Slow, High-Maintenance and Unsafe Overhead Doors

The three sectional overhead doors at a manufacturing plant in Peterborough were causing several issues due to the use of a jackshaft operator. The doors were slow, often requiring repairs due to broken springs and posed a safety hazard for forklifts because they lacked photo eyes.

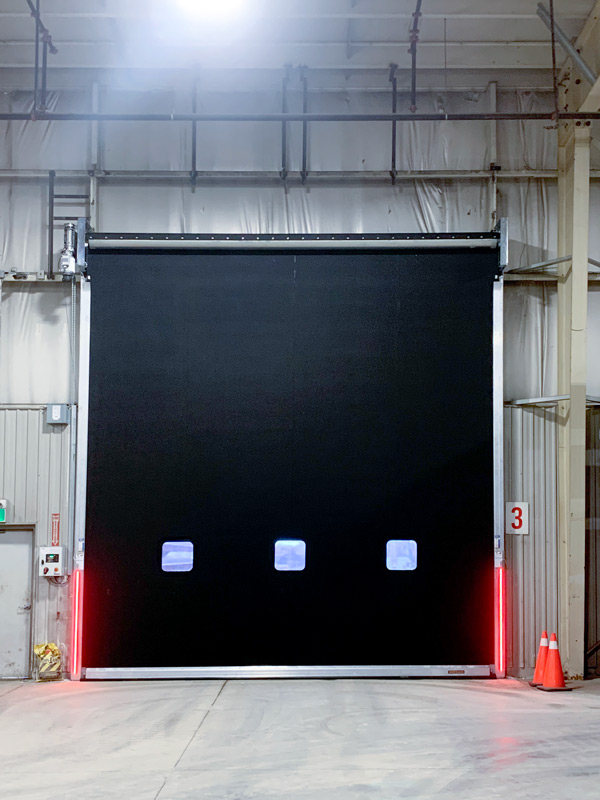

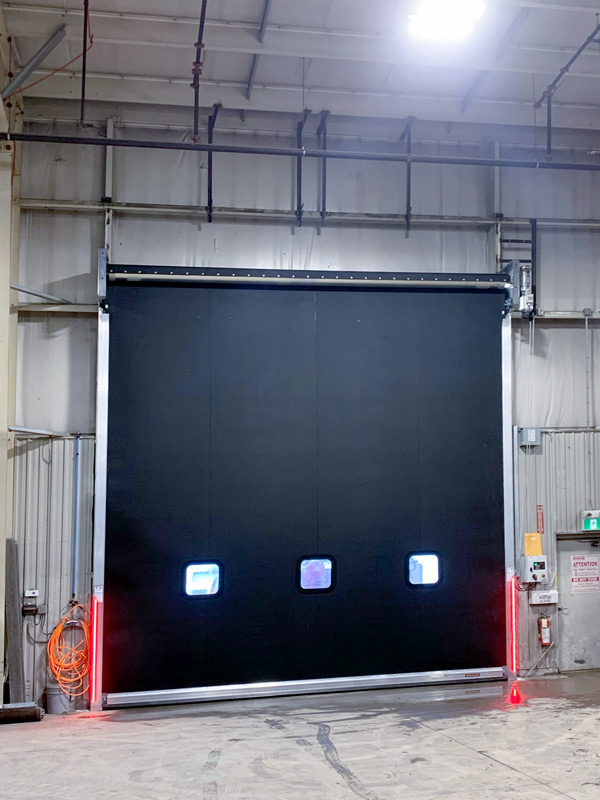

High-Speed Springless Rubber Doors

To address these issues, Northern Dock Systems installed Hormann Direct Drive Springless Rubber Doors. These doors feature a low-maintenance direct drive motor that eliminates the need for springs and other movable parts, reducing the frequency of maintenance and repairs. With opening speeds of up to 64” per second, the high-speed rubber doors are a significant improvement over the old doors.

Natural Light

In addition, the new doors let in natural light through the 16” x 16” windows, creating a well-lit and safe environment.

Integrated Light Curtains

To enhance safety, the doors are equipped with a built-in light curtain. The aluminum guides feature an integrated channel that protects the 92” tall light curtain from accidental impacts and damage.

Safe LED Lite-Advance Door Monitoring Lights

Additionally, the doors have LED Lite-Advance Door Monitoring Lights, which flash red when the doors are closing and turn green once they are fully open. This feature helps prevent forklifts from colliding with the doors when the bottom of the doors is outside of the driver’s line of sight.

Improve Operational Efficiency with Door Transmitters

To improve operational efficiency, the manufacturing plant was also provided with transmitters that let forklift drivers open and close the doors without leaving their vehicles.