Jump to: Information | Photos | Customers | Models | Compare Models | Customizations | Warranty | Specifications

✓ Dock lift tables cost 1/3 the price of a fork truck and will have a quicker ROI: When compared to the long-term cost associated with operating a forklift and manually loading or off-loading a trailer.

✓ Enhance safety: Each dock lift table features a number of safety features including an anti-slip powder coated deck and lip(s), handrails, a 4″ kick plate and a barrier chain across each end.

✓ Superior strength: The LoMaster Stationary Dock Lift (DL) is capable of lifting people and products with a combined weight of up to 20,000 pounds.

✓ Long-lasting: Weather-proof powder coating and maintenance-free lubricated brushing pivot points prolong the lifespan of your dock lift tables.

✓ Versatile: For ground-level loading and unloading where no loading dock is present.

✓ UL/CSA and ANASI MH29.1 approved: Factory pre-wired and tested motor, controls and push buttons.

Information

LoMaster Stationary Dock Lift (DL)

LoMaster Semi-Portable Dock Lift (S)

Rust-Resistant Powder Coat

Featuring a powder coat finish as a standard. The Blue Giant powder coat finish provides a long-lasting and rust-resistant finish and colour. It is available in anti-slip blue, black, grey and yellow.

Safety is Key

Additionally, the standard diamond plate and powder coat grit finish on deck and lip reduces the likelihood of slipping in wet conditions.

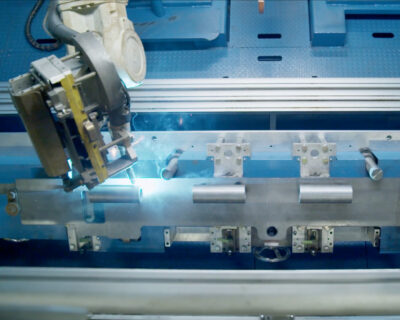

Consistent Quality and Strength

Blue Giant’s state-of-the-art robotic welding ensures structural integrity and uniform quality. Get peace of mind knowing that every weld has the same quality and care put into it.

Safety Toe Guards

8″ bevelled toe guards under the deck on the Stationary Dock Lift (DL) models. Either dock lift table can be upgraded with electric toe guard with magnetic switch and accordion skirts for extra protection.

Safety Barriers and Gates

Each dock lift table comes with personnel restraint chains as a standard. While the Stationary (DL) model can be upgraded to have an interlock swing gate or boom.

In addition, the OSHA compliant 42″ high bolt on steel guardrail comes with mid rail and 4″ kick plate.

Hydraulic Dock Lift Table

These hydraulic dock lift tables come with a remote power pack with 12′ hydraulic hose (three-phase, common voltages) and oil included.

The completely sealed, weather-resistant cylinders vented back to hydraulic tank to prevent contaminant entry.

While the hydraulic pump has a built-in overload relief. In addition to an up-travel limit switch and precision safety velocity fuses on hydraulic cylinders to prevent platform free-fall.

Easy to Operate

The hand-held 24V push button (up/down) control with a 16′ standard straight cord makes it easy to use. While the Stationary Dock Lift (DL) has the option for deck-mount push-button controls.

Make your dock lift table even easier to operate with an optional spring-assisted lips. As a result, you can reduce the manual force required to raise or lower the lip into position.

No Pit or Concrete Pad Needed

The LoMaster Semi-Portable Dock Lift (S) is installed at the dock face and mounted on locating cradles and wear plates. As a result, it bypasses the need to form a concrete pit or pad. With its extremely low profile, the LoMaster S Series provides added versatility for ground-level loading or unloading operations.

Photos

Models

|

LoMaster Stationary Dock Lift (DL)The LoMaster Dock Lift DL Series from Blue Giant provides a safe and efficient way to handle endless materials handling applications at grocery stores, schools, hospitals, postal services and distribution centers, anywhere a low-profile workhorse is required. |

|

LoMaster Semi-Portable Dock Lift (S)The LoMaster S-Series semi-portable dock lift is installed at the dock face and mounted on locating cradles and wear plates, bypassing the need to form a concrete pit or pad. With its low profile, the LoMaster S-Series provides added versatility for ground level loading or unloading operations. |

Model Comparison Chart

| Stationary (DL) | Semi-Portable (S) | |

| Lift system | ||

| Load capacity | 5,000 to 20,000 lb rated capacities | 4,000 to 6,000 lb rated capacities |

| Pit or concrete pad required | Yes Must be mounted in a pit or anchored to a concrete pad. |

No Mounted on locating cradles and wear plates, bypassing the need to form a concrete pit or pad. |

| Deck widths | 60", 72", 84" or 96" See Specs |

72", 84" or 96" See Specs |

| Deck Lengths | 96", 108", 120" or 144" See Specs |

96" or 120" See Specs |

| Safety | ||

| Remote power pack | ||

| Controls | Push button control on 12' straight cord or optional deck mounted push button control. | Push button control on 12' straight cord. |

Customizations

Options

- Swing Gates with interlock

- Electric toe guard protection

- Accordion safety skirting

- Mechanical pop-up run-off guard

- Lip: split, hydraulic, spring assist, extended length, multiple

- Low temperature oil

- Immersion heater for oil reservoir

- 3-10 HP remote powerpacks

- Push button on coil cord

- Deck mounted push button control

Options

- Portable dolly

- 24VAC voltage control

- Key switch on push button

- Aluminum lip

Additional Options

- Warning horn with volume control

- Electric toe guard protection

- Flashing amber beacon

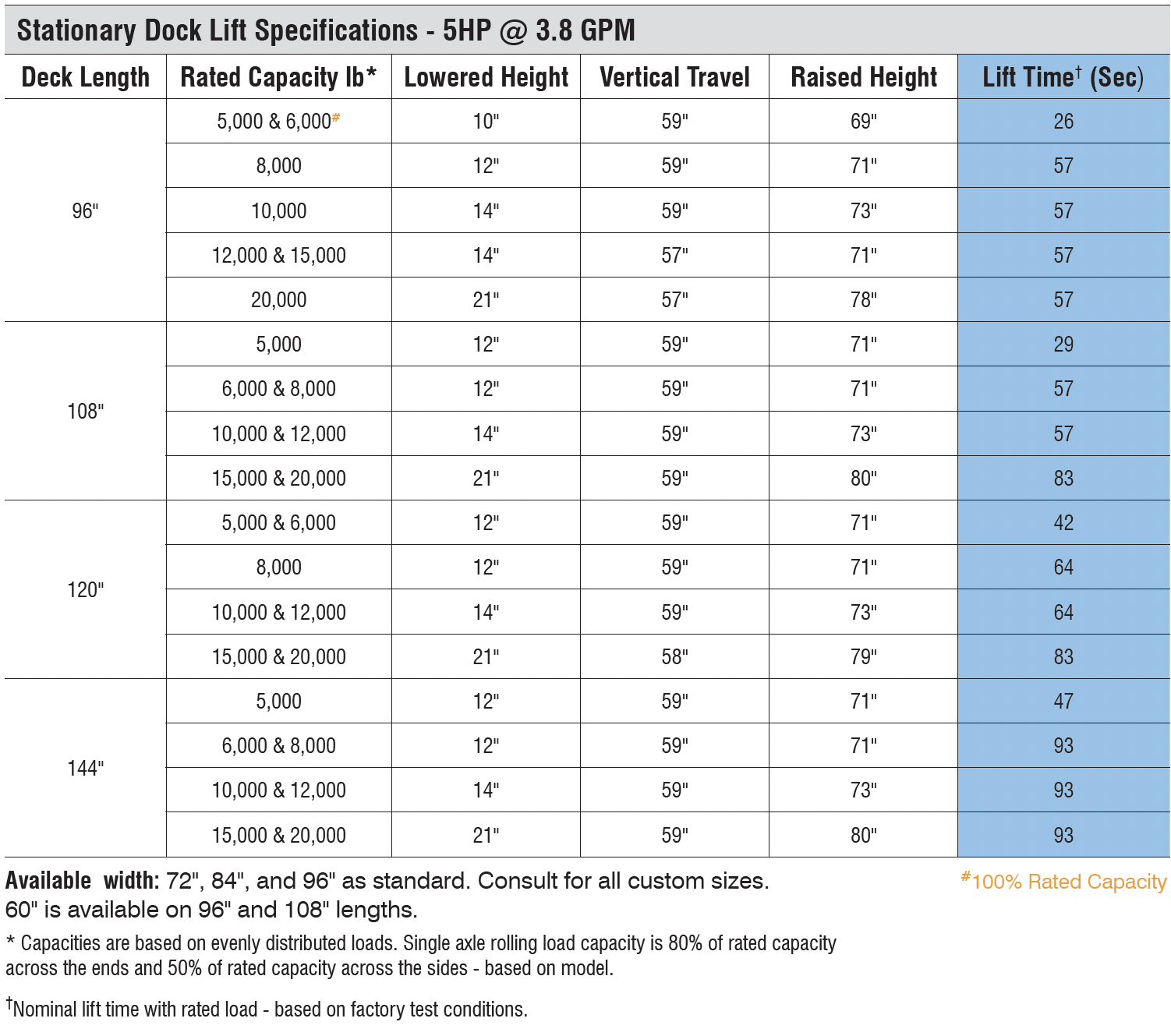

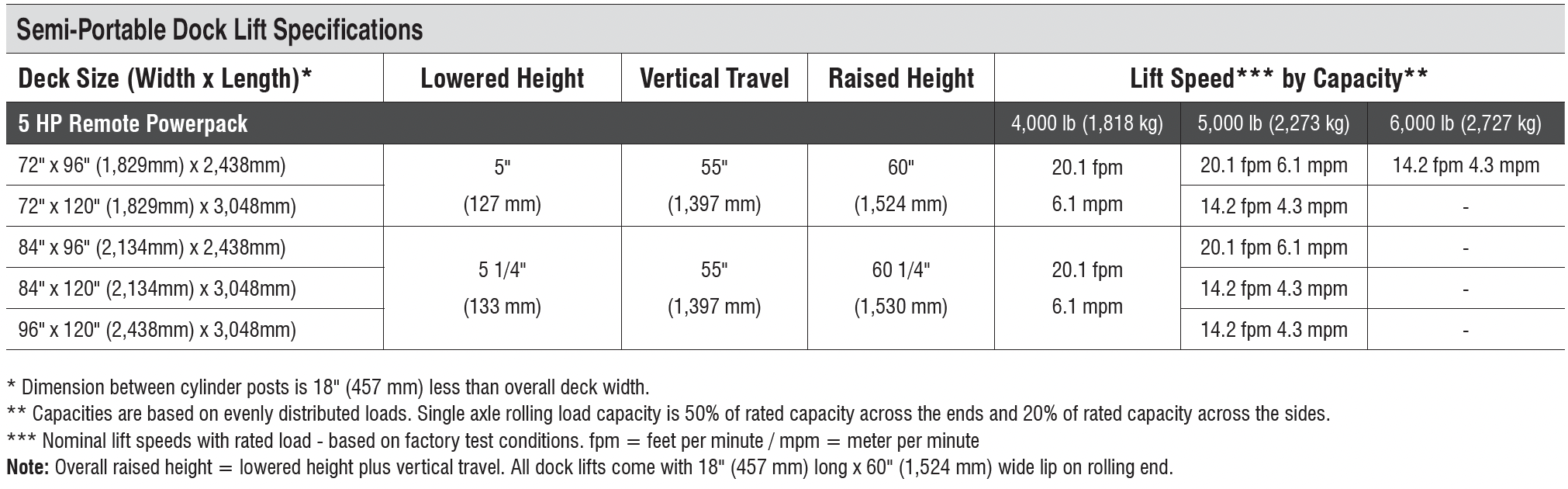

Specifications