Preventive Maintenance Program to Minimize Inefficiencies in Industrial Equipment

Preventive Maintenance You Can Trust

Multi-Point Inspections for Root Cause Discovery, First-Time Fixes, Improving Performance and Passing Audits

Northern Dock Systems’ Preventive Maintenance Program provides specific, multi-point inspection checklists to minimize inefficiencies and downtime in your equipment. We do our due diligence, so you don’t have to sacrifice the well-being of your employees or the operational efficiency of your facility.

Overhead Door Preventive Maintenance Inspection

Dock Leveler Preventive Maintenance Inspection

Pass Inspections with Flying Colours

✓ Regular preventive maintenance ensures you will be prepared for inspections from the Ministry of Labour and/or food agencies. Providing them with a copy of your Northern Dock Systems report is proof that you have done your due diligence to prevent health and safety concerns.

Safety organizations across Canada outline that all equipment should be inspected at least once a year to comply with government safety standards. Our comprehensive, multi-inspection report covers all types of equipment. Following the inspection, you will be provided with a digital copy of our report which highlights any areas of concern and recommends solutions before serious health, safety or operational issues occur.

The PMP Process

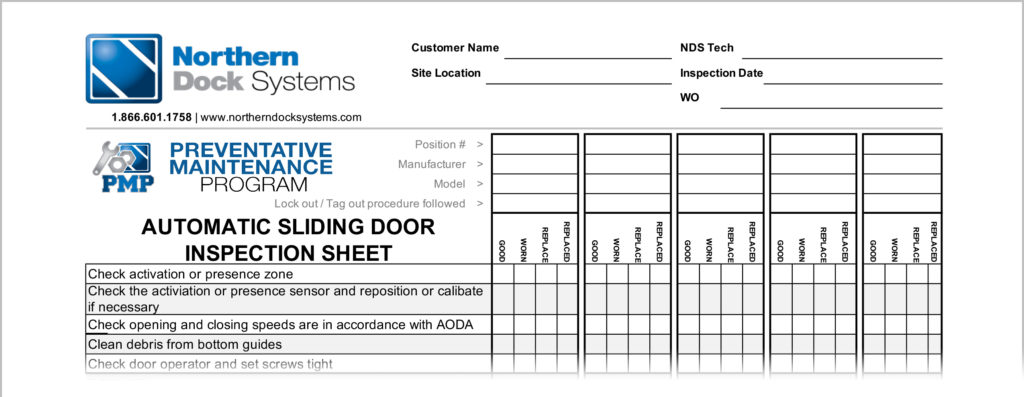

Step 1 – Examine and Evaluate with Multi-Point Inspections

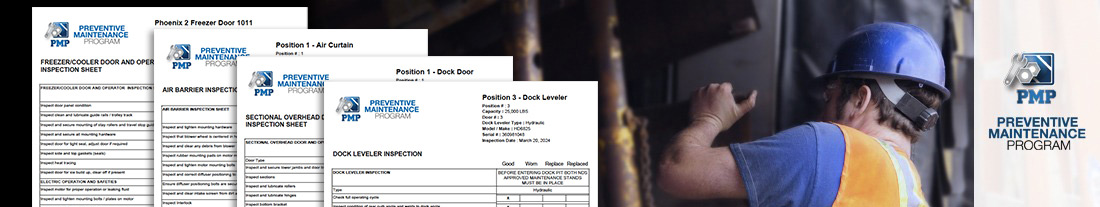

Every piece of docking equipment has a unique checklist of requirements of what needs to be inspected and/or adjusted. This checklist has been developed by our team of experts based on individual manufacturer’s product manuals to ensure peak performance, minimize potential risks and maintain warranty eligibility.

Technicians use over a dozen product-specific preventive maintenance templates to closely monitor equipment conditions and their associated costs. Following the inspection, you will be provided with a digital copy of our report which highlights any areas of concern and recommends solutions before serious health, safety or operational issues occur. All costs are broken down based on the type of problem, piece of equipment, material and labour to help you prioritize any necessary repairs based on your budgetary requirements.

Step 2 – Leave a PMP Report to Pass Inspections

Northern Dock Systems will provide a complete preventive maintenance report so you can retain it for your records. This report has a full breakdown for each piece of equipment to ensure you will be prepared for inspections from the Ministry of Labour and/or food agencies. You can provide them with a copy of your Northern Dock Systems report as proof that you have done your due diligence to prevent health and safety concerns.

Step 3 – Prioritize Repairs Based on Priority and Budget

Every field technician is equipped with a tablet that contains part breakdowns for every manufacturer’s make and model. Once on-site, our technicians will ensure your priority repairs are properly cleaned, adjusted and lubricated for optimum performance.

All PMP Inspections Contain:

Stay Compliant with Provincal Health and Safety Act

The OHSA mandates that every lifting device in a facility be inspected and provided with a written record of inspection as recommended by the manufacturer, and in any case at least once a year. This inspection includes loading docks which are often overlooked.

They also mandate wheel chocks as “A vehicle left unattended shall be immobilized and secured against accidental movement.” Ensure that you have suitable wheel chocks for all your loading docks, to prevent trucks from accidentally rolling away.

For more information, refer to Regulation 851, Section 51-1b and Regulation 851, Section 57 on the OHSA website.

Trusted and Accredited

The certificates, accreditations and memberships verify Northern Dock Systems as a trusted source for providing exceptional service and industry-leading products. We have been working with various companies across Canada since 2002 for installations, construction, retrofitting, and conducting on-site audits and consultations. Our certifications, accreditations and memberships include:

✓ Avetta Member

✓ Canadian Door Institute Member

✓ Certisync Member

✓ Cognibox Member – A Rated

✓ Contractor Check Accredited Member

✓ Contractor Compliance Member

✓ ComplyWorks Member

✓ Electrical Safety Authority (ESA) Member

✓ fmPilot 2 Member

✓ GRMS Member

✓ Hazard Analysis and Critical Control Points (HACCP) Certified

✓ The International Door Association Member

✓ ISNetworld Member Contractor – A Rated

✓ ServiceChannel Member – Preferred Service Member

✓ ServiceChannel Fixxbook Member

✓ WhosOnLocation Member

✓ AAADM Certified

✓ Avetta Member

✓ Canadian Door Institute Member

✓ Certisync Member

✓ Cognibox Member – A Rated

✓ Contractor Check Accredited Member

✓ Contractor Compliance Member

✓ ComplyWorks Member

✓ Electrical Safety Authority (ESA) Member

✓ fmPilot 2 Member

✓ GRMS Member

✓ Hazard Analysis and Critical Control Points (HACCP) Certified

✓ The International Door Association Member

✓ ISNetworld Member Contractor – A Rated

✓ ServiceChannel Member – Preferred Service Member

✓ ServiceChannel Fixxbook Member

✓ WhosOnLocation Member

In addition, we train our licensed technicians to conduct thorough preventive maintenance checks through quizzes and exclusive training videos on an ongoing basis. This ensures that all of our technicians can spot all the necessary fixes needed to keep your facility running as efficiently and safely as possible.

The Northern Dock Systems Difference

- Multiple Technicians on-site

- Fast response times

- Root cause discovery

- First-time fix

- KPI tracking – what gets measured gets done

- Asset management

- Full, online reference library that includes product part numbers, service manuals and troubleshooting guides

- Online chat support

- Email support

- Manufacturer support

- Internet access

- Comprehensive reports for your records for your audits

4.61 Average Star Rating for Service

Out of 5 from our Service Customer Feedback Form as of

Oct 19, 2021.

Our Customers Recommend Our Services

“Our experience with the Northern Dock Systems’ Sales and Service teams has been stellar. The Service Technicians were extremely professional—they arrived on time, adhered to our stringent safety procedures and performed preventive maintenance measures on our high-speed door. Our Project Manager followed up with us after the service as well to make sure all tasks were completed properly. We’re incredibly happy with the entire service experience with Northern Dock Systems and are actively working to put NDS on our preferred vendors list for future service work.”