Project Overview

Back and Leg Strain from Working from the Ground Up

Gardner Denver in Barrie builds air compressors from the ground up. These air compressors can reach up to 5 feet in height. However, the process of building them involves a lot of work at low heights, putting strain on the workers’ backs and legs. Additionally, the assembly work requires the units to be accessed at various heights, leading to employees frequently reaching up and down during the entire assembly process.

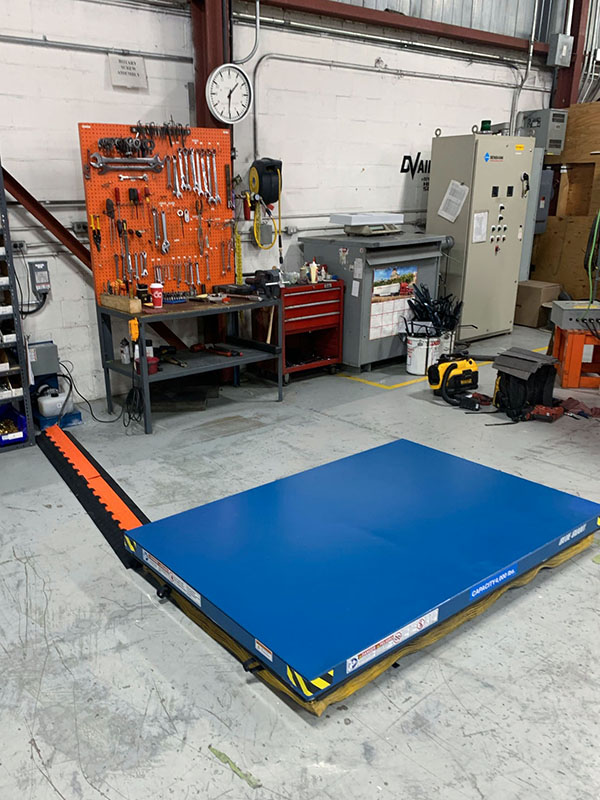

Ergonomic In-Plant Lift Tables

To address these ergonomic challenges, Gardner Denver reached out to Northern Dock Systems for a solution that would reduce strain on their employees’ backs and legs. The solution provided by Northern Dock Systems involved the installation of three Blue Giant Wide Base Scissor Lift Tables. These in-plant lift tables allow workers to elevate the products they are working on to a comfortable waist level, significantly reducing the physical strain.

Different Size Scissor Lift Tables for Different Sized Products

Our technicians installed two different-sized hydraulic lift tables for Gardner Denver: two 60″x96″ lift tables with a 6k capacity and one 48″x72″ lift table with a 4k capacity, designed for the small and large air compressors, respectively. The use of different-sized lift tables ensures that the air compressors are securely supported during assembly.

Easy to Operate and Safe Lift Tables

The in-plant lift tables are equipped with a foot pedal for easy operation and hands-free control as workers engage with the air compressors. Furthermore, all the scissor lift tables are fitted with safety accordion skirting to prevent any accidental pinching incidents.