Every warehouse has them…

Every warehouse relies on them…

Every warehouse MUST have them inspected regularly to avoid costly repairs, replacement costs, downtime and more importantly chance of injury to employees.

Inspect Your Dock Levelers

As a warehouse or office employee, it is easy to forget that the most important part of a dock is underneath the top plate. This is an area where you should only allow trained technicians to have access to. Due to the heavy weight of the dock, combined with time and care a proper inspection takes – a trained professional is required.

It is important to inspect your dock levelers and we highly recommend you talk with our qualified staff to learn more if you have any questions regarding our program or the manufacturer recommendations.

To be proactive, we recommend our preventive maintenance inspection which includes a full, detailed report that outlines a complete breakdown of what is required to ensure safe operation. We also take it one step further to categorize the repairs based on importance. We never guess, estimate or ballpark any project that directly affects the safety of your staff. You can also expect a full breakdown of costs and we are always happy to walk you through our findings.

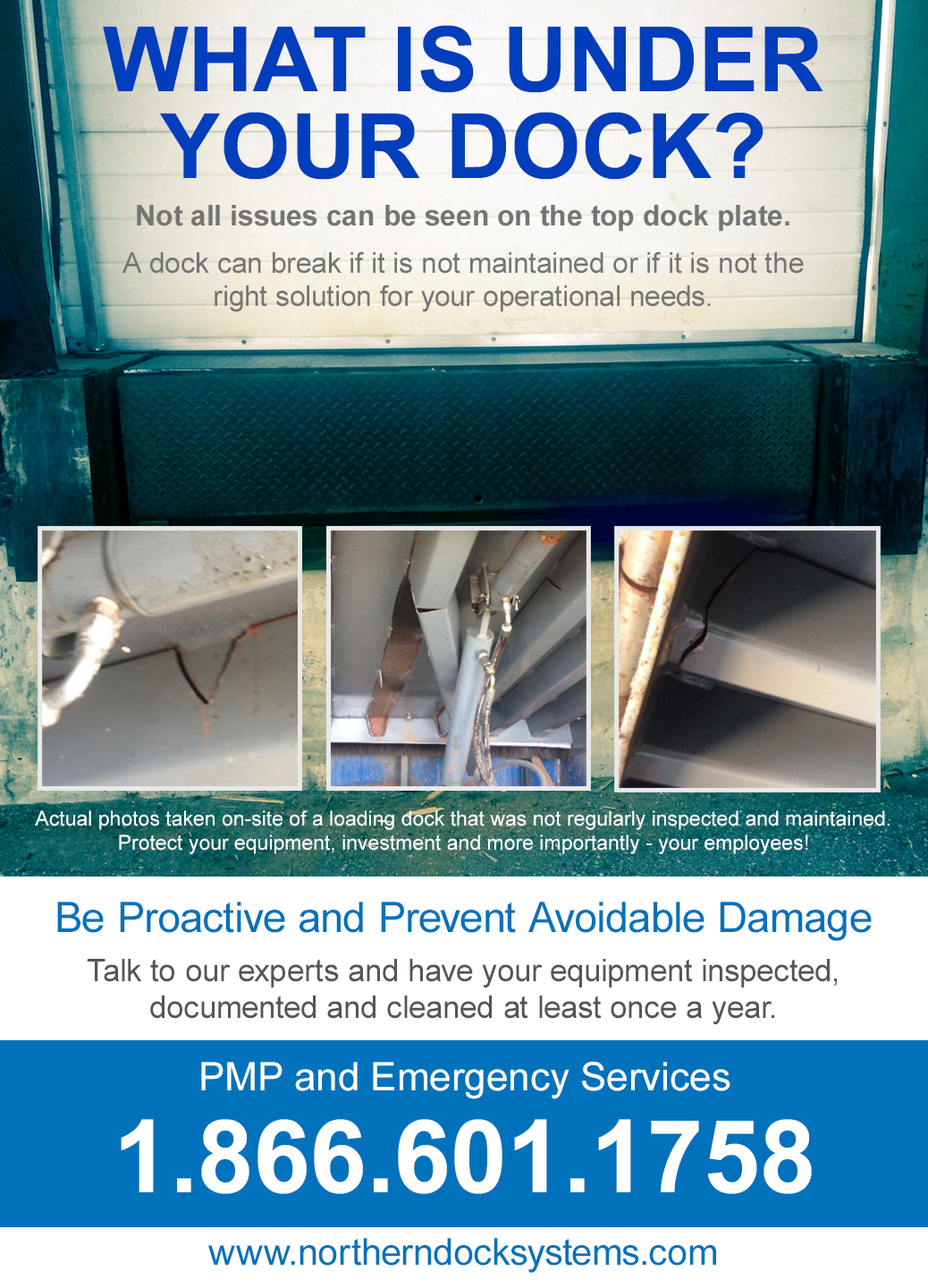

About the above image and statement

The image above helps demonstrate what could happen when you combine a low-grade dock leveler, high use and no maintenance plan. In this scenario, a dock was installed that did not meet the needs of the customer. Over a short time the structure wore out and created a series of cracks and broken components under the top plate. This was an area not easily seen – unless they had used a Preventive Maintenance Program or requested an on-site inspection to ensure safe operation.